High-Efficiency Nonwoven Solutions for Growing Markets – AUTEFA Strengthens Presence in India with Batliboi Partnership

How can a global technology leader meet the rising demand for high-performance nonwoven solutions in a diverse and rapidly developing market like India? AUTEFA Solutions, a renowned manufacturer of machinery and systems for the nonwovens sector, is taking a strategic approach: innovation, efficiency – and strong local representation. In this exclusive interview, Roberto Degrandi, Regional Sales Director for Woollen, Worsted and Nonwovens Technology, shares valuable insights into AUTEFA’s market strategy and the company’s latest milestone: a new partnership with Batliboi Ltd., one of India’s most established industrial solution providers. Operating in major hubs like Delhi, Mumbai, Ludhiana, Tirupur, and Kolkata, Batliboi now represents AUTEFA across the country – enabling closer customer support and stronger market coverage.

Read the full interview to discover how AUTEFA Solutions is shaping the future of nonwoven production – with smart solutions, market foresight, and local strength.

Successful Nonwovens Industry Meet in India - AUTEFA Solutions and Batliboi Host Industry Gathering in Mumbai

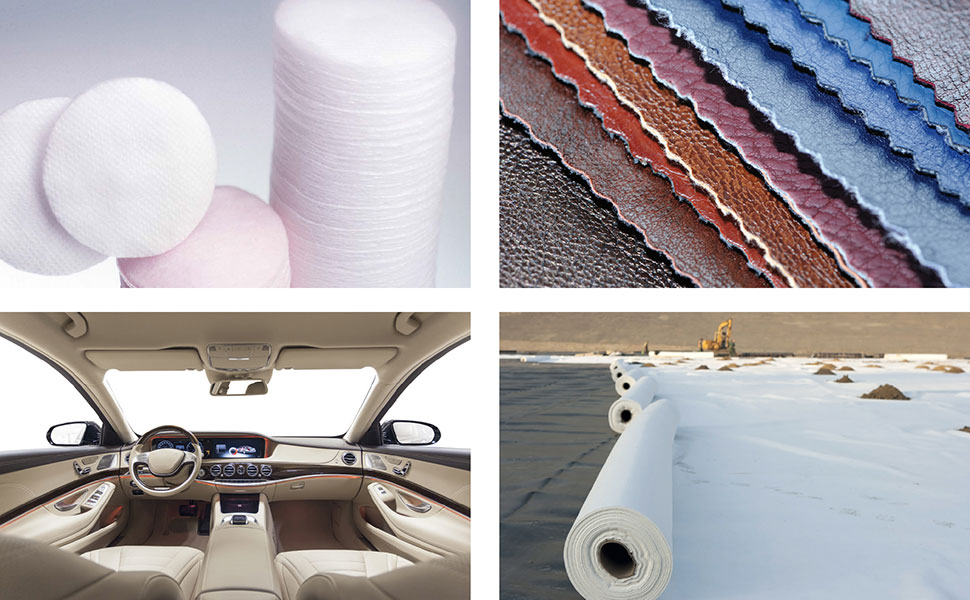

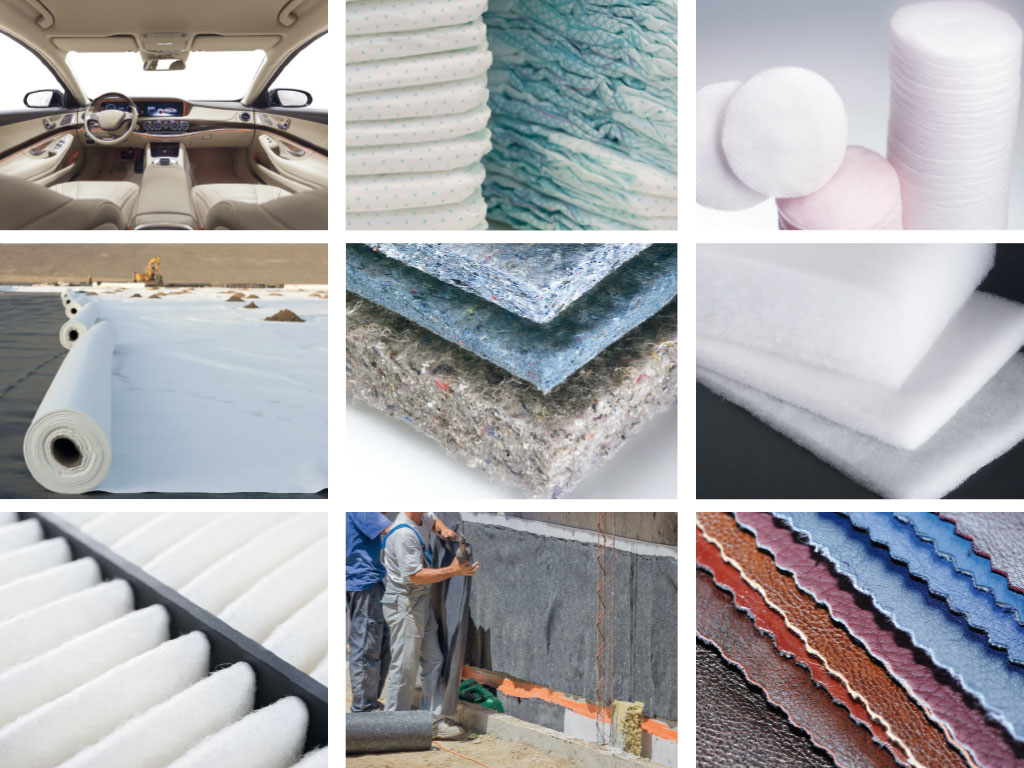

AUTEFA Solutions, together with its valued partner Batliboi Ltd., successfully hosted the "Nonwovens Industry Meet" at the Radisson Blu Hotel in Mumbai on April 9, 2025. The event welcomed a large number of professionals from the Indian nonwovens industry to exchange ideas and explore cutting-edge solutions in nonwoven production. The event focused on showcasing AUTEFA’s advanced technologies, including carded-crosslapped needle punching lines, airlay systems, spunlace, and thermobonding solutions. Attendees had the opportunity to learn how AUTEFA’s technologies help manufacturers achieve high productivity, operational flexibility, and significant energy savings. “We are truly pleased with the strong turnout and the engaging conversations we had throughout the day,” said Roberto Degrandi, Regional Sales Director at AUTEFA Solutions. Alongside Amrish Kumar Gupta, Sales Manager India, he led the presentation of AUTEFA’s latest developments tailored to the growing demands of the Indian market.

AUTEFA Solutions to Showcase Advanced Nonwoven Technologies at IDEA 2025

Sustainable Airlay Solutions for Natural Fibers

With recycling and sustainability driving industry trends, Airlay applications using natural fibers such as hemp, jute, flax, and coconut are gaining significance. Backed by decades of expertise, AUTEFA’s Airlay technology ensures exceptional quality and reliability. The FUTURA V12/R web forming machine provides a compact, cost-efficient solution for processing natural fibers and textile waste. Designed specifically for recycled materials, shoddy, and natural fiber production, the V12/R delivers high-performance technology at moderate costs.

Leadership in Needle Punch and Crosslapping Technology

Carded, crosslapped, and needle-punched lines remain the most widely used processes for nonwoven production, offering versatility and efficiency. With Fehrer Needlepunch technology, AUTEFA Solutions is a recognized market leader in needle looms and crosslappers, known for exceptional quality, robust machine design, and long machine lifetime. Combined with outstanding technical support and continuous innovation, AUTEFA Solutions ensures maximum efficiency and superior results for nonwoven manufacturers.

AUTEFA Solutions presents advanced nonwovens technology at CINTE/Techtextil 2024

André Imhof, CEO of AUTEFA Solutions Austria, emphasizes: " Sustainability is an important aspect of our commitment. We have also noticed that interest in economical production lines for nonwovens manufacturing continues to grow. We are also seeing a strong trend towards digital transformation, where digital technologies are being used to increase production efficiency and quality. Upgrades and retrofits are also crucial to further improve product quality, operational safety and environmental sustainability.”

The Airlay V21/R - K12 from AUTEFA Solutions offers a versatile solution for processing natural, sustainable and recyclable fibers. Airlay systems offer the highest product quality, efficiency and reliability by opening the material down to the individual fiber, allowing high flexibility in fiber selection.

AUTEFA Solutions is proud to have supplied complete needle punching geotextile lines to Suhail Industries,

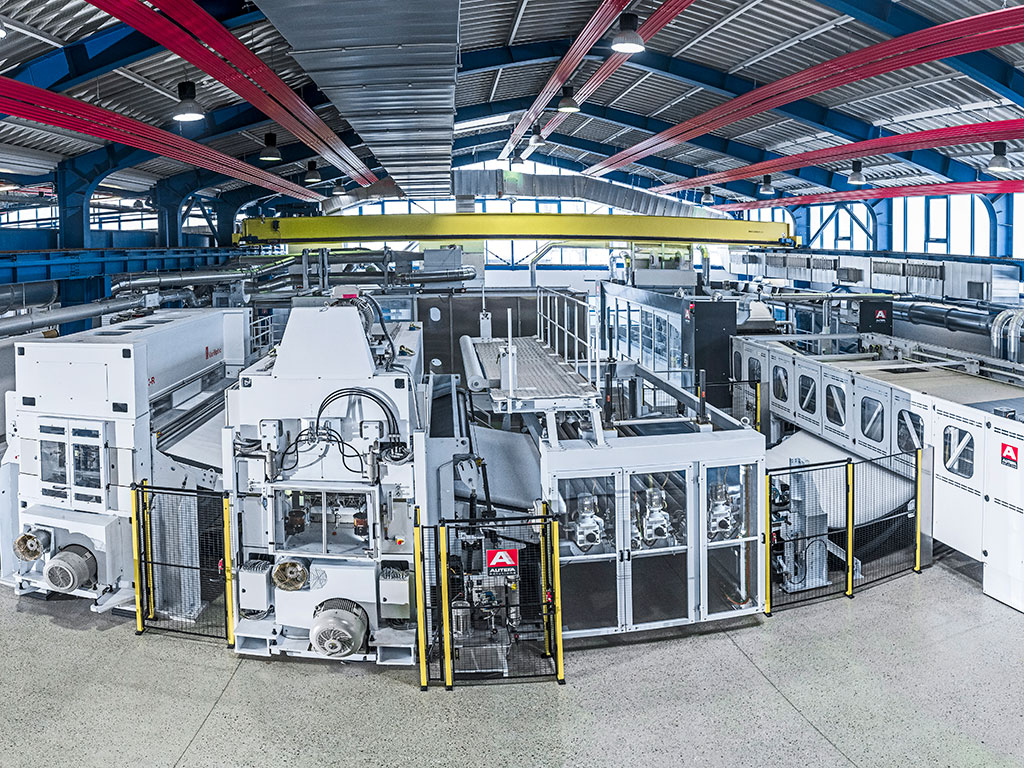

AUTEFA Solutions is proud to have supplied complete needle punching geotextile lines to Suhail Industries, a leading holding group in Qatar. By using state-of-the-art technology, Suhail Industries demonstrates its ability to adapt to the ever growing market requirements and to react promptly and flexibly to individual customer needs. Driven by the increasing demand in recent years, the decision to invest in a new geotextile production line underlines the commitment to meet the growing demand for geotextiles in Qatar and international markets.

The selection of AUTEFA Solutions as a partner reflects their extensive experience and market leadership. AUTEFA Solutions, a leading supplier of turnkey nonwoven lines and machines. AUTEFA Solutions boasts a rich and storied history that spans several years, marked by a relentless pursuit of excellence and innovation in the field of nonwovens technology. Established as a company dedicated to providing cutting-edge solutions for the textile industry, AUTEFA Solutions has evolved into a global leader in turn-key nonwovens lines and machines. The company's comprehensive offerings cover a wide spectrum of applications, including lines for the production geotextiles, ensuring that it remains a versatile and integral player in various sectors.

AUTEFA Solutions excels in the premier league of needling

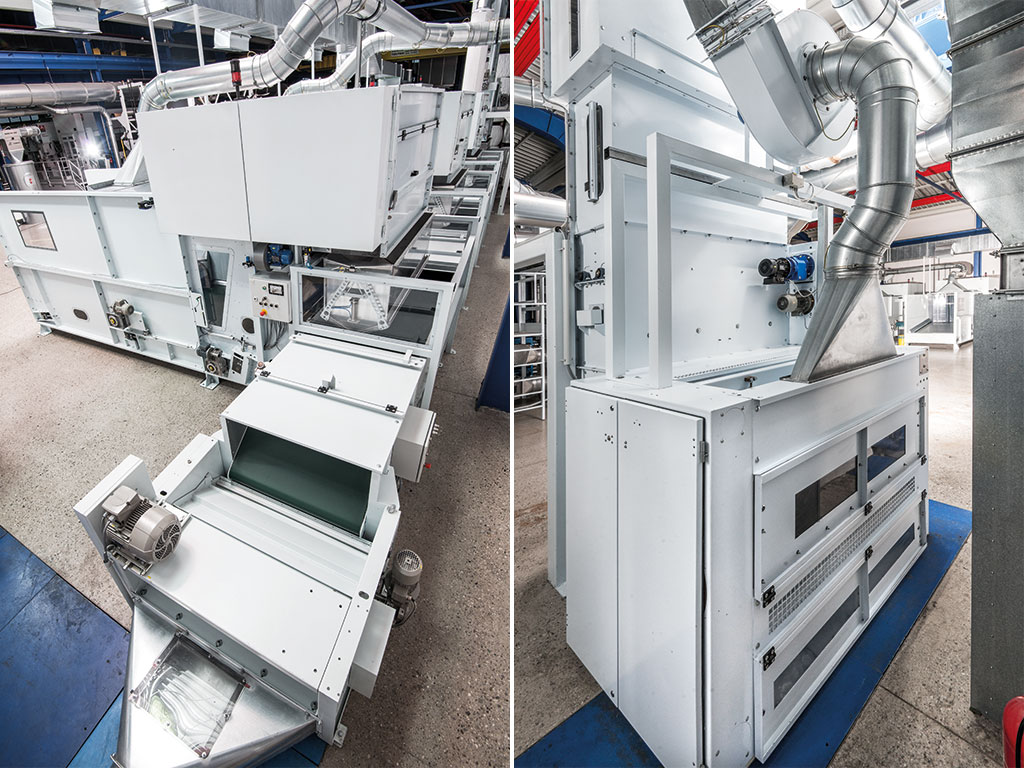

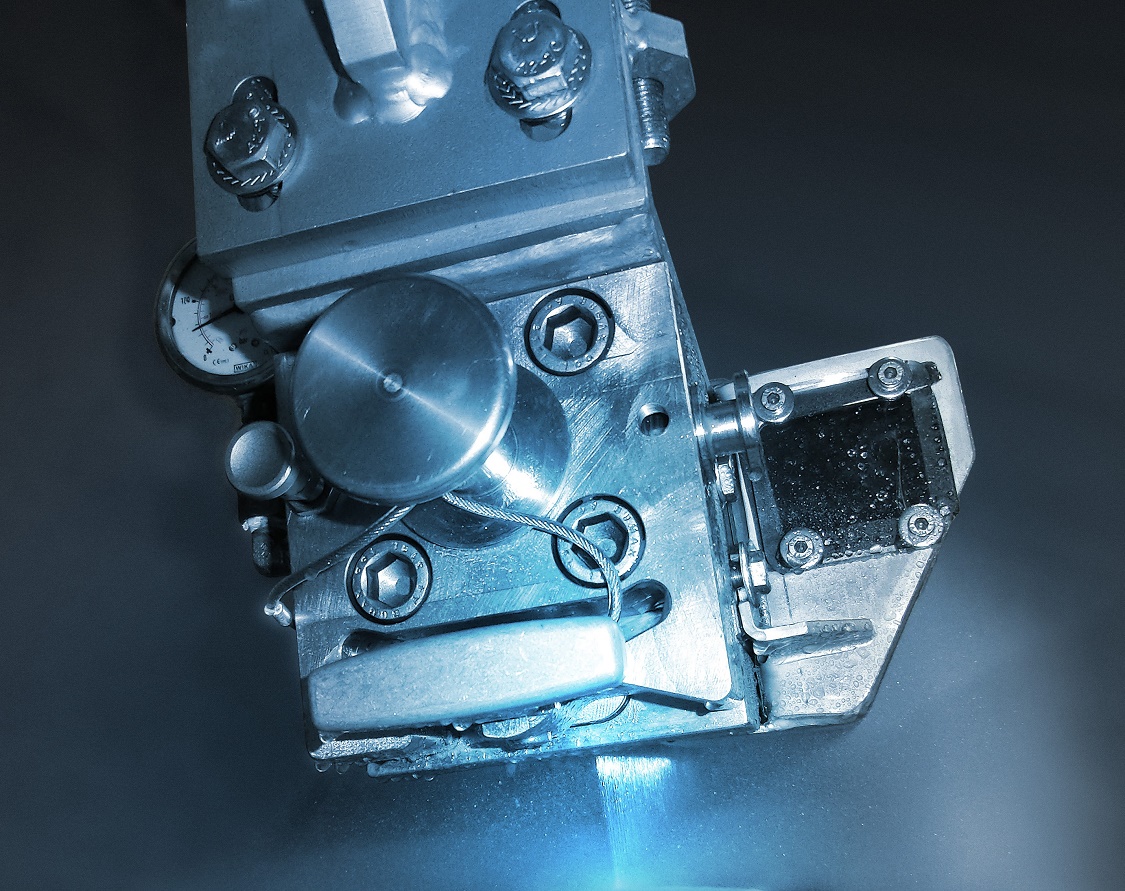

The production of papermaking felts is one of the most complex processes in the nonwovens industry. It combines the highest quality standards with unusual requirements for fabric width and desired basis weight. Papermaking felts are used in the drying stage of the papermaking process and play a crucial role in determining the surface quality of the final product.

The production of papermaking felts requires the highest precision, especially in the needling process over the entire working width. AUTEFA Solutions achieves this with ingeniously designed rigid steel frames that allow minimal vibration even at working widths of up to 17 meters.

ITMA 2023- a brief review

ITMA 2023 was set to be a transformative event in the world of textiles. Under the overarching theme of 'Transforming the World of Textiles', ITMA 2023 showcased the latest advances and trends in the industry with a particular focus on four key sub-themes: advanced materials, automation and the digital future, innovative technologies, and sustainability and the circular economy. The AUTEFA Solutions team was pleased to see the great interest in our machines and technologies.

More information

AUTEFA Solutions - Pioneer in sustainability with innovative solutions

As sustainability becomes an increasingly important consideration in the fashion industry, the demand for textile circularity is growing significantly as consumers and companies alike seek solutions to recycle fast fashion. In response to this trend, AUTEFA Solutions offers innovative solutions designed to process and reuse various types of fibers, including reclaimed, natural and man-made materials. The compact and economical machine for processing all natural fibers such as coir, sisal, jute, hemp and cotton as well as animal hair/wool and textile waste is the Airlay V12/R Aerodynamic Web Forming Machine. Fed by a hopper feeder, the Airlay V12/R is capable of producing nonwovens in a weight range of 400 - 8000 gsm.

AUTEFA Solutions at Index 2023 – Technical innovations and customer service on a new level

At INDEX in Geneva from April 18-21, 2023, AUTEFA Solutions will showcase its latest technical developments in the field of nonwoven production technology. The focus is not only on classic mechanical engineering with its ambitions for higher-faster-further, but also on the protection of resources and on excellent, individual customer support within the scope of the "Assessment for Thermal Systems".

Water - the source of life - is the basis of the spunlace process that AUTEFA has been actively developing for years. The company’s wide product range offers cutting-edge technology for web forming as well as hydroentanglement and finally, drying of the produced nonwovens.

JUNE 21-24, 2022 TECHTEXTIL, FRANKFURT

During Techtextil, visitors will experience the economic and technical advantages of AUTEFA Solutions as a full line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace, and thermobonding lines. AUTEFA Solutions is committed to technology that is both innovative and sustainable.

More information

AUTEFA Solutions supplies needle punching lines for Geotextile production to Confidence Infrastructure Ltd., Bangladesh

AUTEFA Solutions announces that it will supply two complete needle-punching Geotextile lines to Confidence Infrastructure Ltd., one of the leading Engineering solutions providers from Bangladesh. Using state‐of‐the art technology, Confidence Infrastructure Ltd., is able to adapt to the continually growing market requirements and to react promptly and flexibly to individual customer needs. A growing demand in the last years led to the decision to invest in a two new Geotextile production lines.

The scope of supply includes complete solution from fiber opening and blending, Double Doffer card, crosslapper Topliner with web profile control WebMax and needle punching machines Stylus NL with winders. Confidence Infrastructure Ltd. will produce 300-600gsm polypropylene and polyester nonwoven geotextile with maximum width up to 4.2m. The majority of the production will be consumed in Geobag application for erosion control. More information

Rocketing demand at Shanghai nonwovens event- Autefa technology serves spunlace boom and more

The nonwovens sector is looking forward to a celebration of both technical and commercial progress at the upcoming SINCE conference and exhibition in Shanghai. Worldwide markets for some applications – especially spunlaced products for hygiene and sanitizing wipes – have rocketed during the pandemic. And AUTEFA Solutions is ready to cater for a continuation of this “huge demand” with its latest systems being presented at the event.

Says AUTEFA Solutions CMO Marco Fano: “Our unique web-forming technology ideally meets our customers’ needs at this time, and we see the upward trend in order intake being sustained in future, particularly in combined card and crosslapper solutions. Our advanced spunlace manufacturing systems are able to deliver high standards of quality and performance, with the all-important advantage of rapid investment payback.” More information

AUTEFA presents innovative solutions for the textile industry

Higher productivity, sustainability and Industry 4.0 compatible solutions will be the highlights of AUTEFA presentations at the forthcoming ITMA Asia+ CITME in Shanghai. Latest machines from the business units Nonwovens Technology, Woollen Carding Technology and Baling Technology will be featured at the event later this month, at Hall 7, Stand A24.

The key advantages of the full range of the AUTEFA Solutions textile equipment portfolio will be explained, with a detailed focus on a number of specific innovations. Visitors will hear about the economic and technical benefits of AUTEFA as a systems supplier for full nonwovens lines in technology for carded-crosslapped needlepunching, aerodynamic web forming, spunlace production, and thermobonding. More information

Optimization of the flor quality and increase of energy efficiency

The study of optimizing pneumatic fiber flow from the individual processes within opening & blending to reduce operating costs (energy) and improve the nonwovens quality of the plant. This is the approach of Maximilian Speiser‘s Master‘s Thesis, supervised by Prof. Dr. Volker Jehle (Reutlingen University), in cooperation with AUTEFA Solutions Germany GmbH, which was awarded the VDMA Prize of the Walter Reiners Foundation at the end of 2020. In the fiber preparation of nonwovens, in addition to the various mechanical processes, there’s also pneumatic fiber conveying. The aim of the study was to build on this initial situation, an approach to increase energy efficiency within maintaining the floor quality of the card. An increase in energy efficiency must not be at the expense of the process safety, i.e. an increase in the probability of clogging. More information

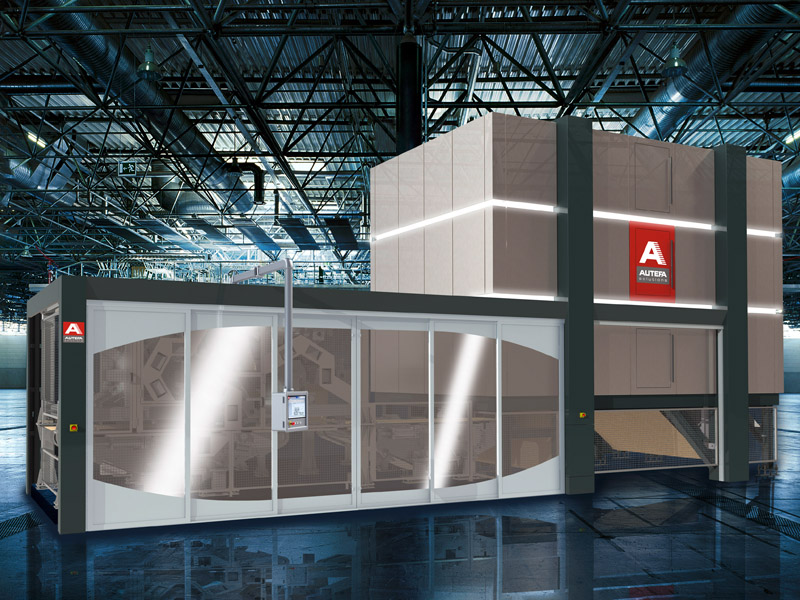

AUTEFA Solutions conducted successful spunlace trials in the Nonwovens Competence Center in Linz, Austria together with Lenzing and their team behind the VEOCEL™ brand

AUTEFA Solutions spunlace line with the Hydroentanglement Machine V- Jet FUTURA is available for further customer trials using the full portfolio of the company's Nonwovens machinery “from bale to fabric” including opening and blending, web forming, hydroentanglement, drying as well as cutting and winding. Recently, a team from Lenzing that is known for their VEOCEL™ branded cellulosic nonwoven fibers, was invited for trials at AUTEFA Solutions Nonwoven Competence Center in Linz, Austria.

Christoph Machill, Head of Business Unit Spunlace:

”Our new line, targeted with full power and know how, over the last years is now ready for the market. We are focused to offer solutions also with regard to the processing of biodegradable products.”

More information

AUTEFA Solutions, well prepared with highly competitive solutions for CINTE/Techtextil 2020

"The spunlace sector is still competitive for end product manufacturers. Autefa Solutions offers complete lines for the production of direct and crosslapped spunlace products. The web forming process, consisting of the Injection Card and Crosslapper Topliner series, is the key for high and consistent nonwoven fabric quality. Marco Fano, CMO Autefa Solutions: “There is still a huge demand for Spunlace Lines and our unique web forming technology meets our customers’ requirements. We are positive, our order intake, especially for card- crosslapper combinations, is very good. This advanced Spunlace technology offers a quick return on investments with our customers appreciating the performance and quality of Autefa Solutions Lines. Furthermore, we recently sold several needle punching machines for spunbond applications following request for machines with high production.” More information

Hydroentanglement sets the pace in nonwovens growth

"The hydroentanglement sector recorded the highest growth rate in 2019, at slightly more than 5.5%, according to the latest statistics from EDANA."...“"As the world continues to discover the important role of nonwovens in protecting healthcare staff and patients through medical devices and personal protective equipment, such as surgical masks, respirators, gowns, drapes and coveralls during the Covid-19 pandemic, our ongoing commitment is to work with partner associations throughout the world, also to harmonise nonwoven production and sales statistics, and our positions on trade classification rules,” said Pierre Wiertz, general manager, EDANA. “This, together with the now improved ISO nonwovens definition, should give the whole industry the visibility it deserves.” Read the full report, published in Sustainable Nonwovens e-bulletin - 03.04.20

Lightweight construction with natural fibers - Thermoplastic hybrid composites with wood fibres

Weight reduction is one of the key challenges in developing sustainable vehicles. The use of renewable raw materials in the form of natural fibres, such as flax, kenaf or hemp, is state of the art and is mainly used in the automotive industry. The reasons are numerous. Natural fibres are much cheaper than carbon fibres and lighter than glass fibres. This results in cost and weight advantages. Excellent mechanical properties can also be achieved. Finally, the use of natural fibres offers a clear ecological advantage. Read the full report in English, published in Plastverarbeiter March 2020 issue.

Sustainable production is playing a major part in the latest advances in the spunlace sector

A new hydroentanglement machine with better performance, energy savings and the next generation of machine handling. AUTEFA Solutions new V- Jet Futura machine incorporates all these concepts. Sustainable Nonwovens catches up with Marco Fano, Managing Director, AUTEFA Solutions, to discover how sustainable production is playing a major part in the company's latest advances in the spunlace sector. Read the full report, published in Sustainable Nonwovens October/ November 2019.

ITMA 2019

During ITMA 2019 AUTEFA Solutions presented the new Hydroentanglement Machine V- Jet FUTURA that incorporates all these concepts. The FUTURA concept was also extended to a new generation of Airlay cards. Moreover, all textile business groups, Nonwovens, Woollen Carding and Fiber Logistic Technology were presented with new machines fully designed and manufactured in Europe. Solutions for increasing productivity, quality and the energy saving potential of Spunlace production lines was a huge topic since ITMA 2015. Examples for such new solutions are the Square Drum Dryer SQ-V dryer that saves 35 percent of drying energy and the V- Jet injector for spunlace which consumes up to 30 percent less energy with improved performances. Both technologies were recently introduced to the market. To achieve even better performance with less energy – this is especially important in the hygiene industry, as energy and fibres represent one of the biggest cost factors in this segment. Service and technical support is very important for customers. For that reason, AUTEFA Solutions introduced Service 4.0 which covers all aspects of improving the performance of a production line during lifetime.

Techtextil 2019

Experience future-proof solutions for improving quality and productivity

During ITMA 2019 AUTEFA Solutions presented the new Hydroentanglement Machine V- Jet FUTURA that incorporates all these concepts. The FUTURA concept was also extended to a new generation of Airlay cards. Moreover, all textile business groups, Nonwovens, Woollen Carding and Fiber Logistic Technology were presented with new machines fully designed and manufactured in Europe. Solutions for increasing productivity, quality and the energy saving potential of Spunlace production lines was a huge topic since ITMA 2015. Examples for such new solutions are the Square Drum Dryer SQ-V dryer that saves 35 percent of drying energy and the V- Jet injector for spunlace which consumes up to 30 percent less energy with improved performances. Both technologies were recently introduced to the market. To achieve even better performance with less energy – this is especially important in the hygiene industry, as energy and fibres represent one of the biggest cost factors in this segment. Service and technical support is very important for customers. For that reason, AUTEFA Solutions introduced Service 4.0 which covers all aspects of improving the performance of a production line during lifetime.

Customer day in India

AUTEFA Solutions welcomed customers from the Indian Nonwoven Industry

AUTEFASolutions welcomed customers from the Indian Nonwoven Industry On January 18, 2019 AUTEFA Solutions realized a Symposia for the Indian nonwoven industry. AUTEFA was pleased to welcome a high number of potential customers and industry experts in Mumbai with the target to share latest developments in Needlepunching, Spunlace and Airlay technology as well as retrofit solutions. Alexander Stampfer, Regional Sales Director, AUTEFA Solutions explains: “Our overall goal is to be close to our customers to better understand their needs. As a full line supplier for carded- crosslapped needlepunch lines, spunlace lines and thermobonding lines we offer a wide product range for the nonwovens sector, including fiber preparation, carding, needling, thermobonding, hydroentanglement, drying as well as end-of-line equipment. The customer today is more demanding and requires lowest possible Total Cost of Ownership (TCO). “ The mayor nonwoven industry trends of high productivity paired with low maintenance cost and high flexibility for various nonwovens products increase the demand for top quality machines from AUTEFA Solutions. More information

Economic solutions

Lighter weight products with no compromiseon strength are driving the growth ofnonwoven geotextiles, says AUTEFA.

AUTEFA Solutions reports that thedemand for geotextiles isgrowing with the globaleconomy and stringent government regulations are reinforcingtheir usage.The main advantage of nonwovenscomes from their economic production,with output of up to to 1,800 kg/h, thecompany says. The demand is now forlighter weight products of between 90-120 gsm without compromisingstrength, although AUTEFA's technology can be engineered to produce weights ofup to 1,600gsm.The company manufactures bothsingle machines and full lines fornonwoven needlepunched staple fibregeotextiles, as well as needle looms forspunbonded geotextiles and scatteringmachines and needle looms for geosyn-thetic clay liners. More information

Techtextil NA

AUTEFA presents solutions for thermo- and acoustical- insulation nonwovens fabrics, carpet production and advanced fiber processing

In the construction, residential and automotive market, efficient thermal and acoustic insulation materials are key factors that contribute to energy saving and to the reduction of natural resources consumption. The aerodynamic web forming process with AUTEFA Solutions random card Airlay K 12 stands for an improved MD:CD ratio and a three-dimensional web structure. During the process the fiber material is opened up to the single fiber; this enables a high versatility regarding fiber choice. The Airlay K 12 offers the special advantages when it comes to lighter weights and high loft fabrics. The increased opening capabilities distinguish itself for PET as well as fiberglass fiber processing.

During Techtextil, visitors will experience the economic and technical advantages of AUTEFA Solutions as a full line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace, and thermobonding lines. AUTEFA Solutions nonwovens lines meet customers’ requirements for quality web formation, bonding, active weight regulation, and minimal maintenance. More information

AUTEFA Solutions at ITM, 2018 - serves the Turkish Nonwovens market

Giacomo Meucci, Regional Sales Director, AUTEFA Solutions: “We see an increasing demand in reliable and cost-efficient production lines for the highly-competitive Automotive market. Our customers need high-speed lines and an improved quality”. The Turkish nonwovens market covers almost all application fields. Typical applications of needle-punched nonwovens are the production of artificial leather, automotive felts, carpets and carpet backings, insulation materials for thermal and noise insulation, geotextiles, industrial wipes and technical felts. During ITM, visitors will see the economic and technical advantages of AUTEFA Solutions as a full line supplier for carded- crosslapped needlepunch lines and thermobonding lines. AUTEFA Solutions nonwovens lines meet customers’ requirements for quality web formation, bonding, active weight regulation and minimal maintenance. More information

SINCE 2017

Autefa Solutions focuses on customers’ requirements

During SINCE, visitors will be informed about the economic and technical advantages of AUTEFA Solutions as a full line supplier for carded- crosslapped nonwovens lines, needlepunch nonwoven lines, spunlace and thermobonding lines. AUTEFA Solutions nonwovens lines meet customers’ requirements for quality web formation and web bonding, active weight regulation, and minimal maintenance. As nonwovens producers are facing more competition, they are looking for reliable and economic machines. More information

Setting new machinery standards

AUTEFA Solutions’ exhibit at Techtextil focused on its economic and energy-efficient nonwoven machinery portfolio. Managing director, André Imhof, explains more... As nonwovens producers face more competition, they are looking for reliable and economic machines. The best total cost of ownership (TCO) is the key to success. We are seeing a significant number of customers that hesitate, due to higher prices, to replace existing machines or invest in new machines. For all these customers, AUTEFA Solutions introduced its new “LineONE” concept. More information

Published on Techtextil News July 2017 by WTIN