Weight uniformity and strength - quality characteristics for papermaking felts

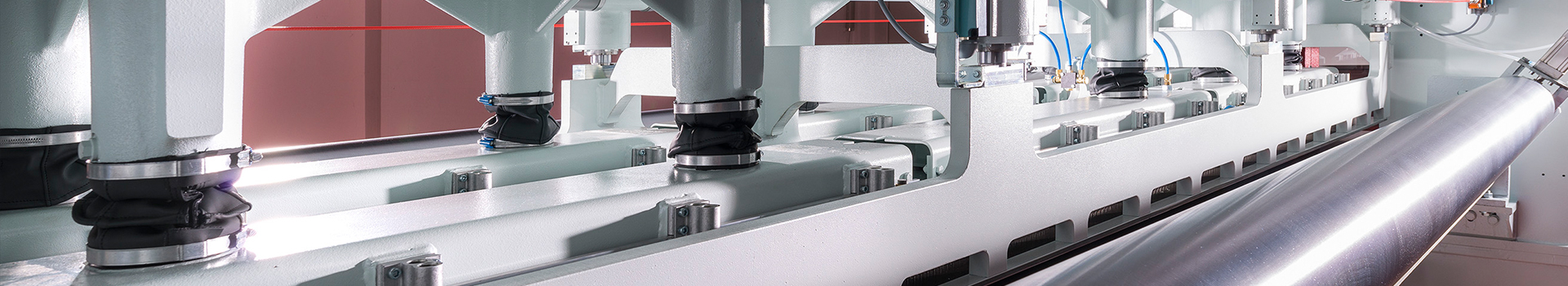

Lines for the production of papermaking felts

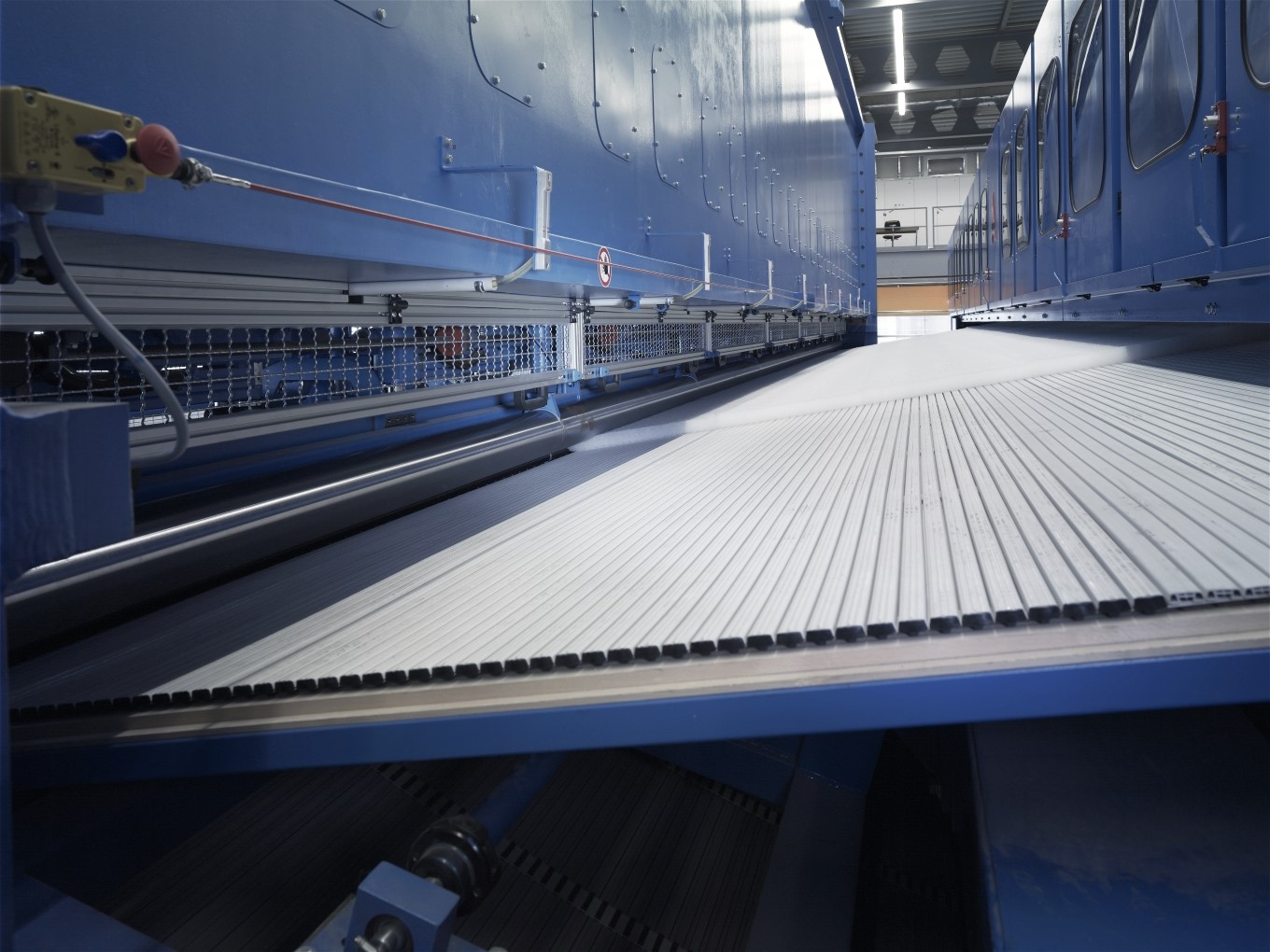

The production of papermaking felts is one of the most complex processes in the nonwovens industry. It combines the highest quality requirements with unusual demands on the fabric width and basis weight to be produced. Papermaking felts are used in the drying process during paper production and have a decisive influence on the surface quality of the final product. Papermaking felts must have excellent basis weight uniformity. In papermaking, paper quality is improved if the felts have high strength and run with low vibration on the paper machines. It is also important that the felts are produced in a virtually continuous process, as this is the only way to avoid indentations at the splices.

The design of plants for the production of papermaking felts requires special know-how; AUTEFA Solutions' plants are always planned and designed according to the customer's specifications. The many years of experience of the specialists and the continuous service and support make AUTEFA Solutions' customers successful.

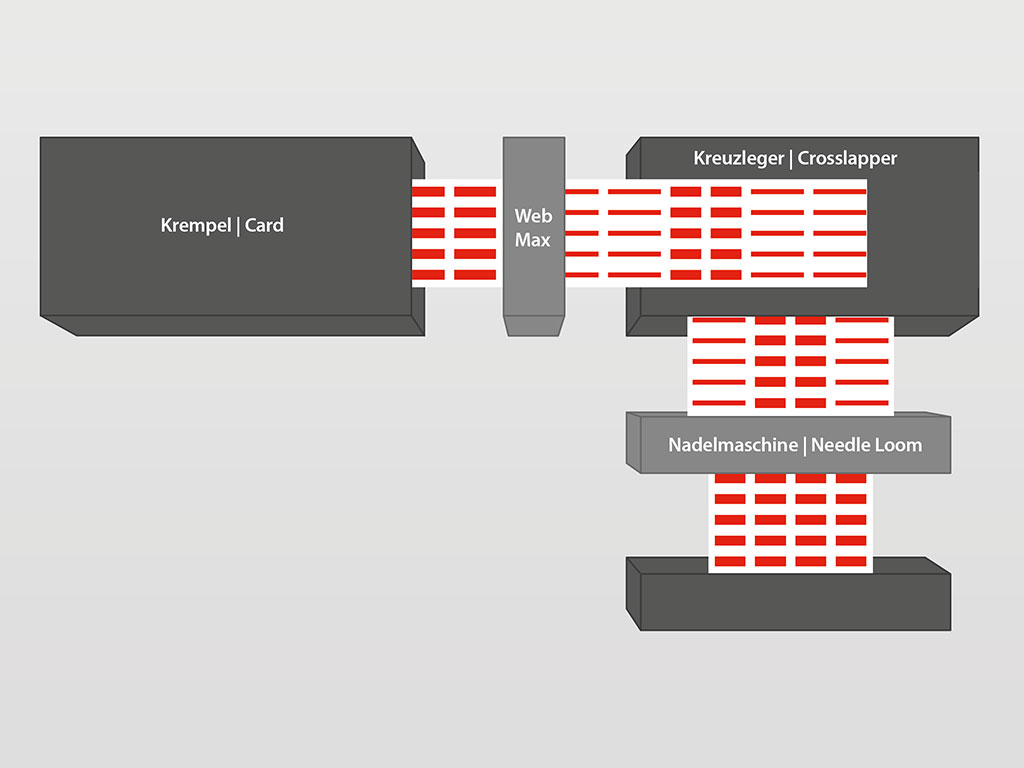

- Masterfelt Card working width 2,5 m

- Crosslapper Topliner CL 4000 PF, working width up to 17 m

- Needle Loom working width 1,2 m - 17 m

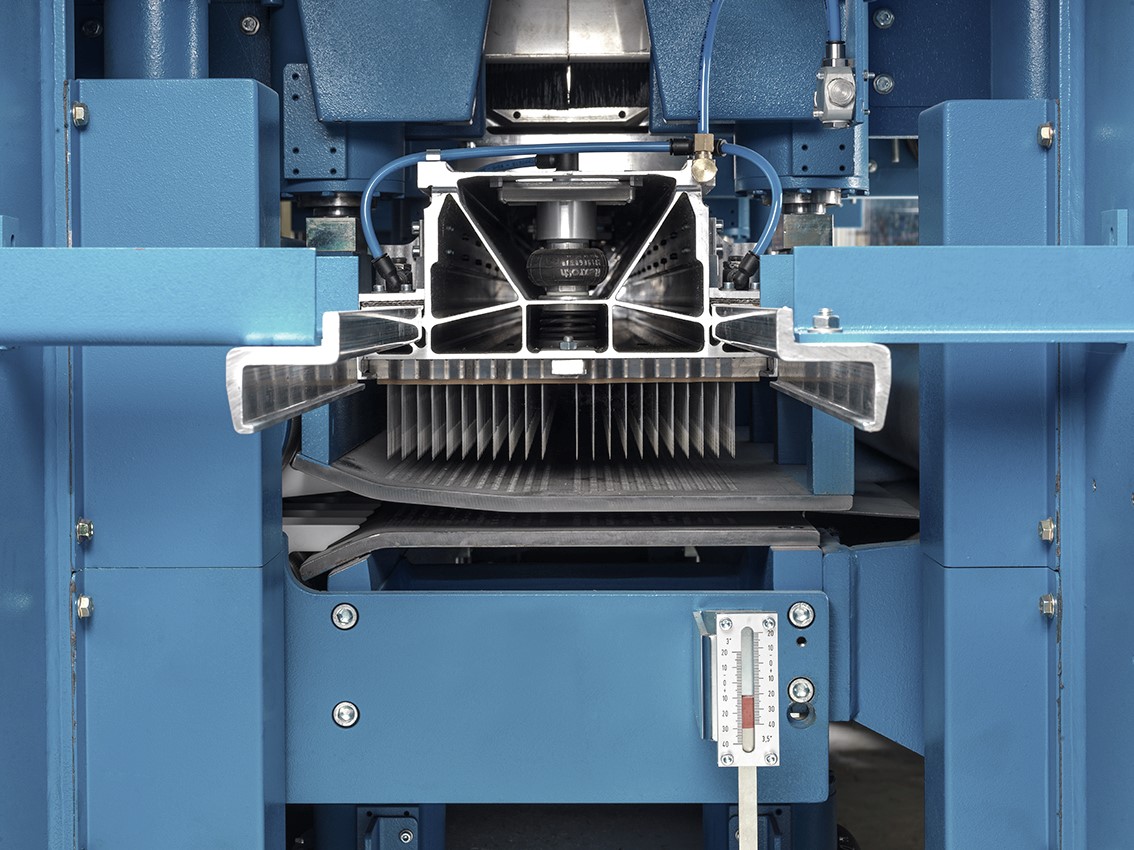

- Needle Loom Stylus NL16 and Stylus NL19

- Max. continuous stroke frequency 1200 rpm

- Vertical stroke 50 - 70 mm

- Horizontal stroke 0 - 6 mm

- Needle pattern up to 4000 needles/m

- Crosslapper with WebMax for web profile control

- Web profile control in MC/DC

- Recipe sequence control for optimized poduct changes: 70% less waste, more profit, enhanced sustainability

- Advanced technology for papermaking felt lines, service and support from a single source

- High quality and reliability due to assembly and testing in Europe

- Local service in Europe, USA and China by AUTEFA trained personnel

- Ability for future modular software and hardware upgrades

- Best total cost of ownership due to low operating costs and long service life

The basis for paper machine felts are fibers made of 100% polyamide PA. The fibers used must have both water absorption capacity and mechanical strength to meet the requirements of the felting process.