Nonwovens Competence Center Linz

Where ideas transform into advanced products

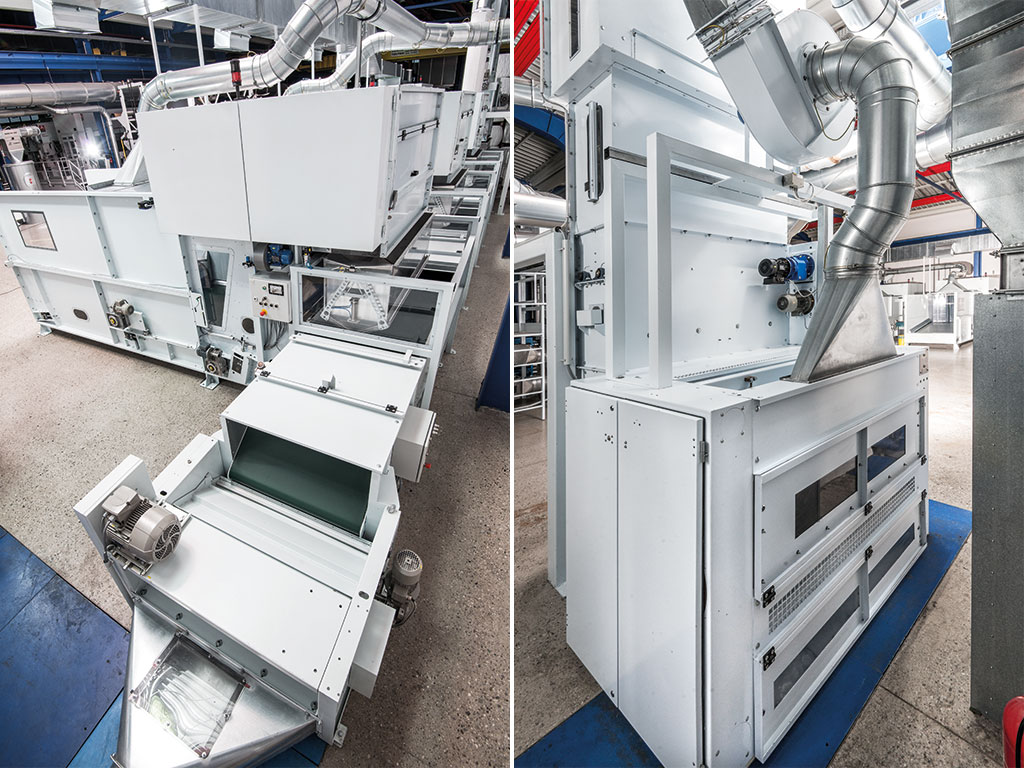

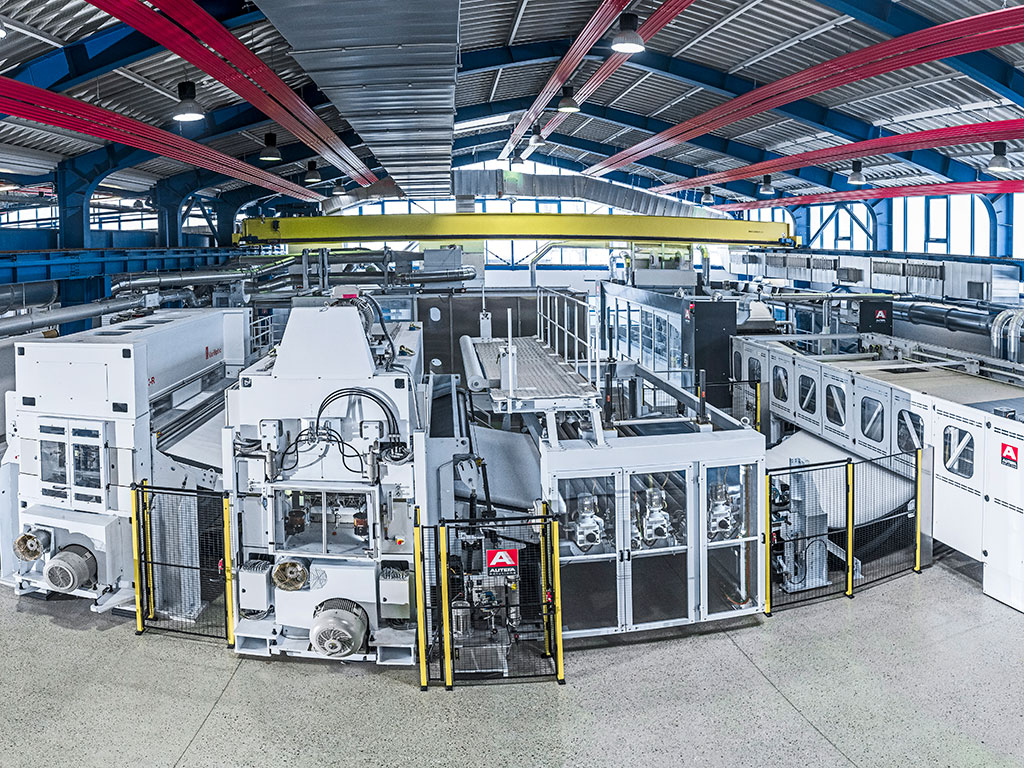

The AUTEFA Solutions Nonwovens Competence Center, located in Linz, Austria, is a beacon of innovation and product development for our valued customers. Our state-of-the-art facility offers exceptional trial capabilities to support our customers in their quest to develop innovative, advanced products. With four nonwovens production lines for needling, thermobonding, and hydroentanglement, we provide a comprehensive platform for product development and testing. The equipment installed within our Competence Center serves as a window into the quality, workmanship, capability, and performance of AUTEFA Solutions' machinery. It's a place where ideas take shape and the boundaries of what's possible are pushed further than ever before. Our commitment to product development extends far beyond our equipment. Our team of specialists, driven by a passion for innovation, works tirelessly to optimize the technical and technological aspects of your product based on both your specific needs and the demands of the market. With four production lines, we provide

- Fiber evaluation: We carefully evaluate the key components of your nonwovens to ensure they meet your standards.

- Machine and line configuration recommendations: Our expertise helps you determine the most efficient setup for your production needs.

- Performance and quality optimization: We work closely with you to fine-tune the performance and quality of your products.

- Customer Sample Production: We create samples that clearly demonstrate the capabilities of our machines and your product.

- Process development for special applications: If your product has unique requirements, we develop customized processes to meet those needs.

- Comprehensive trial reports: We provide detailed trial reports that provide insights and data critical to your product development process.

- Customized training programs: We ensure that your team is equipped with the knowledge and skills needed to maximize the potential of our machines.