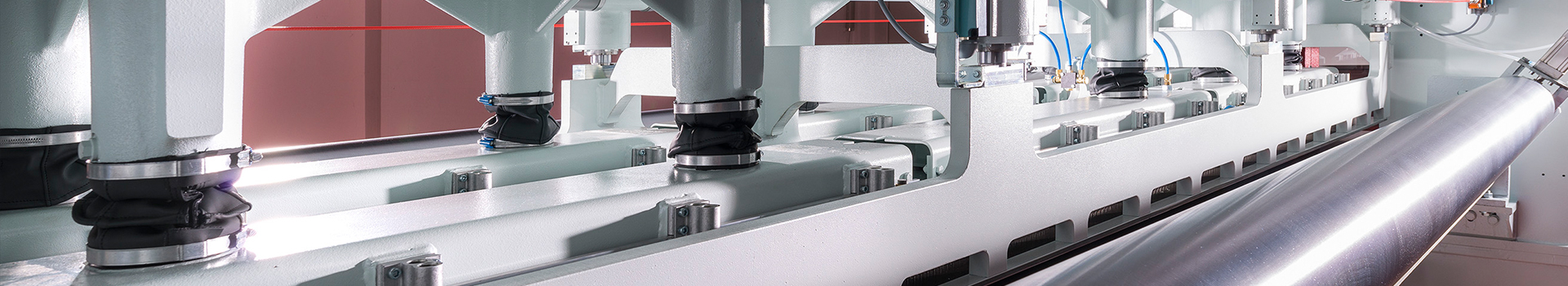

AUTEFA Solutions LineONE

AUTEFA Solutions is a leading supplier of turnkey nonwoven lines and machines for carded-crosslapped needle punching, spunlace and thermobonding. In addition to complete equipment, we offer comprehensive engineering services including start-up and production support as well as quality and capacity guarantees. Machines from the LineONE series by AUTEFA Solutions represents an advanced, cost-efficient solution tailored to diverse industry requirements. Designed for maximum reliability and efficiency, the LineONE system ensures outstanding performance while optimizing operational costs.

LineONE offers a smart investment opportunity. Its well-balanced combination of quality, affordability, and innovative technology makes it the preferred choice for manufacturers seeking cost-effective and high-performance solutions.