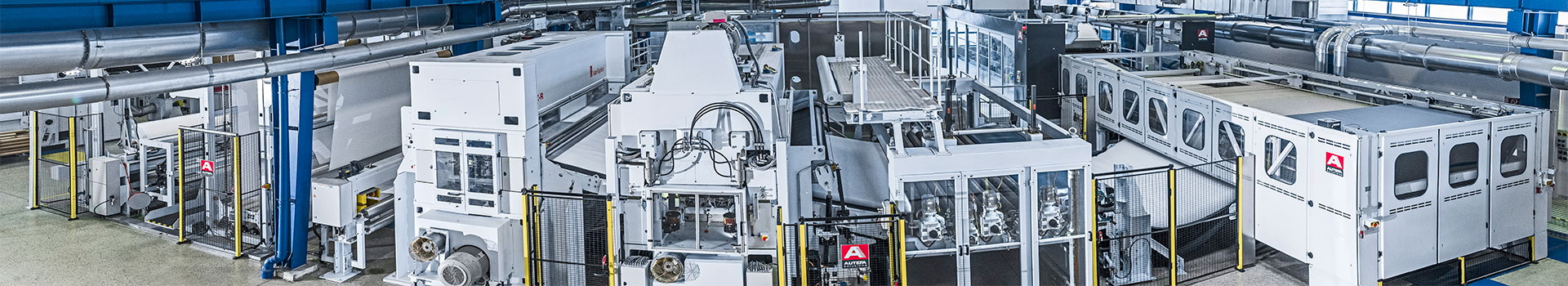

AUTEFA Solutions – Your Partner for High-Quality Needle Punching Lines

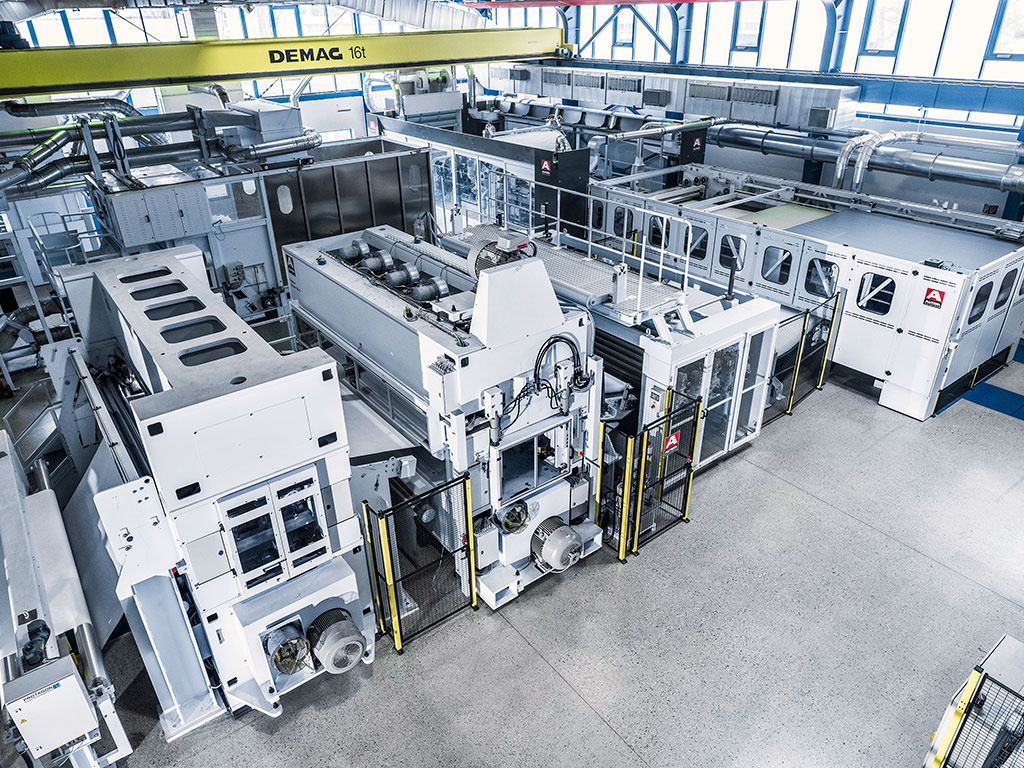

AUTEFA Solutions is a leading supplier of carded-crosslapped needle punching lines, offering also turnkey solutions and state-of-the-art machinery for various nonwoven processes, including, airlay, spunlace, and thermobonding. With a strong focus on high productivity, low maintenance costs, and flexibility, AUTEFA Solutions meets the growing industry demand for efficient, high-quality production lines. Our proven technologies enable manufacturers to produce a wide range of unique nonwoven fabrics. Beyond equipment, AUTEFA provides comprehensive engineering services, from start-up and production support to quality and capacity assurance, ensuring seamless integration and optimal performance.

With the renowned companies AUTEFA in Friedberg (Bavaria, Germany), Fehrer in Linz (Austria), FOR and OCTIR in Biella (Italy), and Strahm Hi-Tex in Switzerland, AUTEFA Solutions represents a group with a rich tradition and decades of success in the global market.

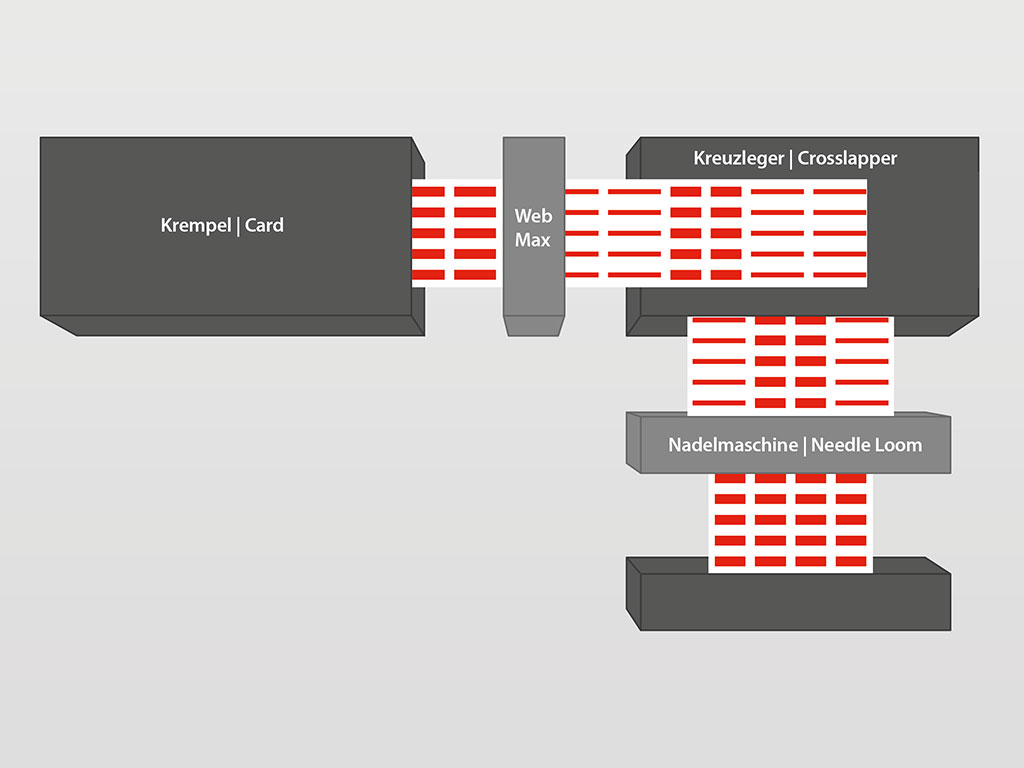

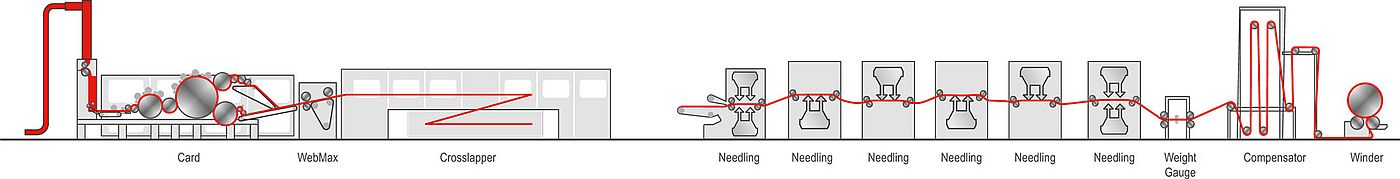

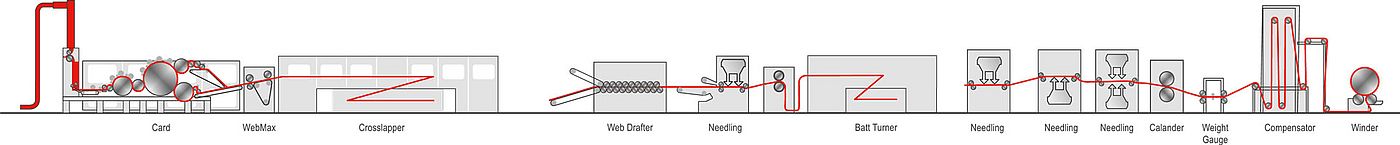

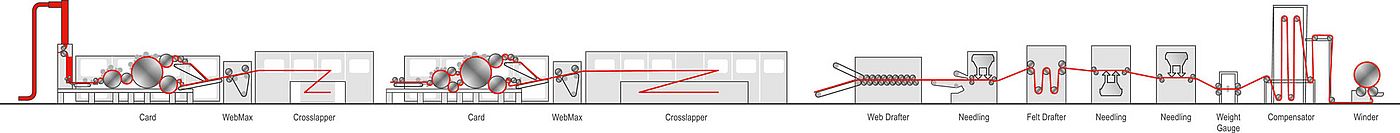

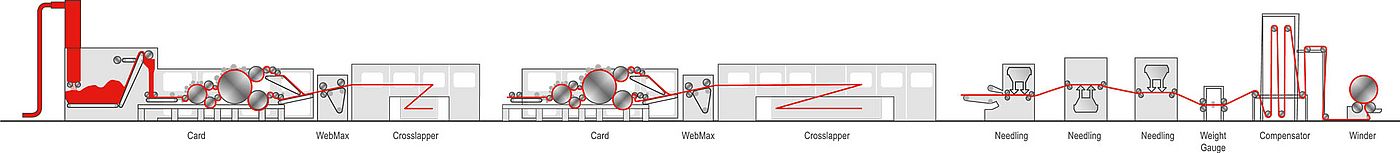

Needle punching is a web bonding technology that provides strength through mechanical interaction – without the aid of chemical or thermal influences. The fiber web is formed in a carding machine, which is then layered by a crosslapper and compacted by a webdrafter. This configuration enables high flexibility concerning product weight range and product width.It is important to bring the unconsolidated web even and closely to the needling zone to enable a reliable and fast infeed to the needle loom. During the actual needle punching process, special needles with small barbs repeatedly penetrate the nonwoven fabric. As the needles move through the material, they catch and interlock the fibers, creating a strong bond within the structure. This targeted fiber entanglement results in high material strength. A wide variety of settings – from individual needle properties to various machine equipment – enable different product characteristics.