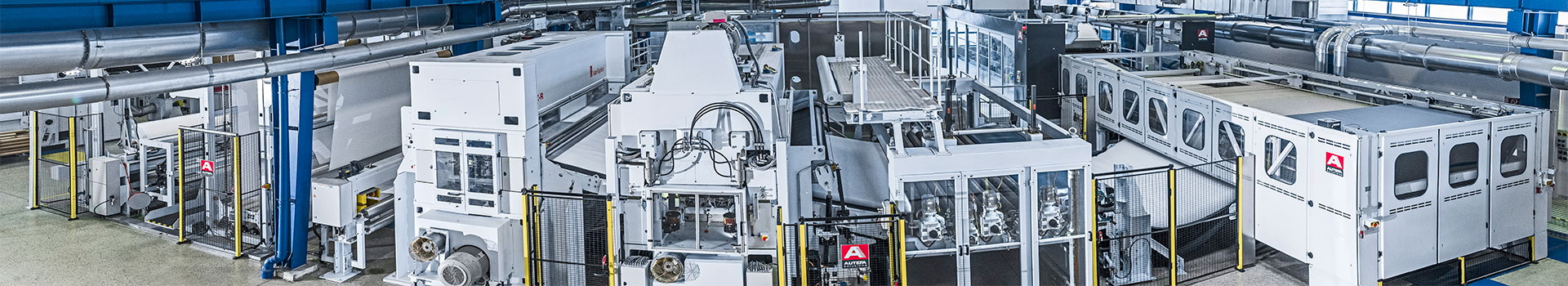

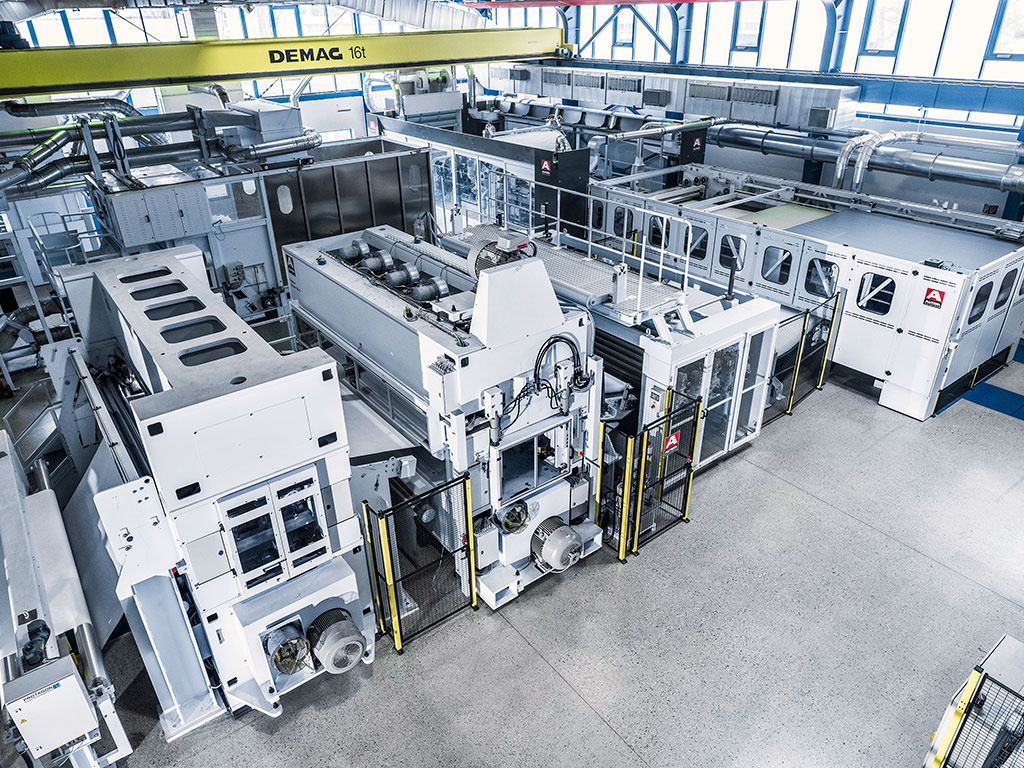

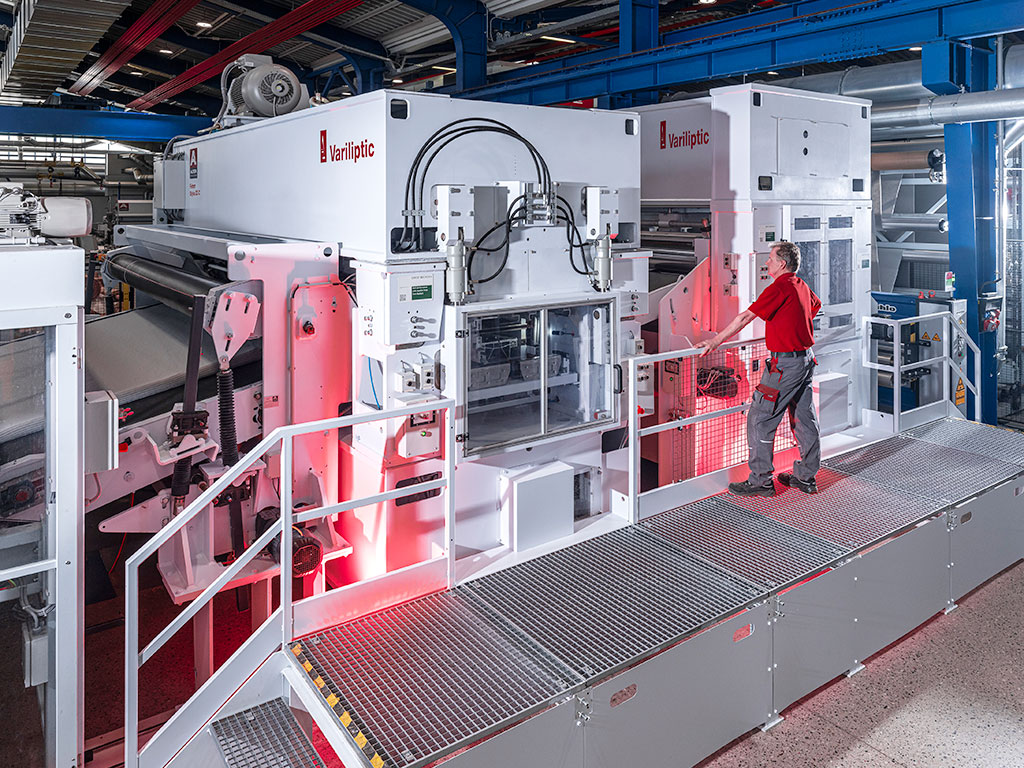

Needle punching for geotextiles

AUTEFA Solutions offers complete lines for the production of needled geotextiles. Geotextiles are generally flat or three-dimensional textiles. These nonwovens are used for separation, reinforcement and filtration in the construction of highways, airfields, railways, sports fields, drainage ditches, dams and dykes. Despite their strength and durability, geotextiles are light and easy to lay. They are used as a building material in civil engineering, water engineering and traffic route construction and are an important aid in geotechnical securing work.

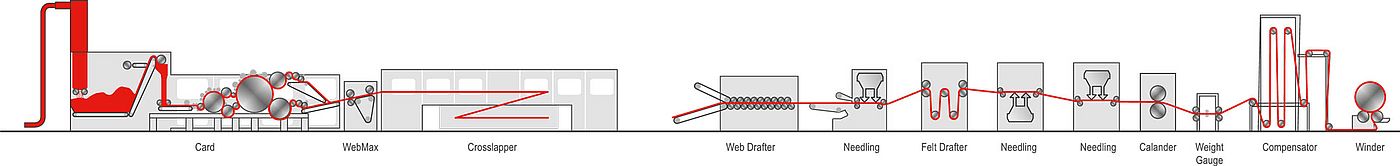

- Product width up to 7 m

- Web product weight range 70 – 1200 gsm

- Polypropylene, Polyester and Natural Fibers Nonwoven Geotextile/ Geosynthetic

- Constant web quality

- Excellent uniformity

- High Production

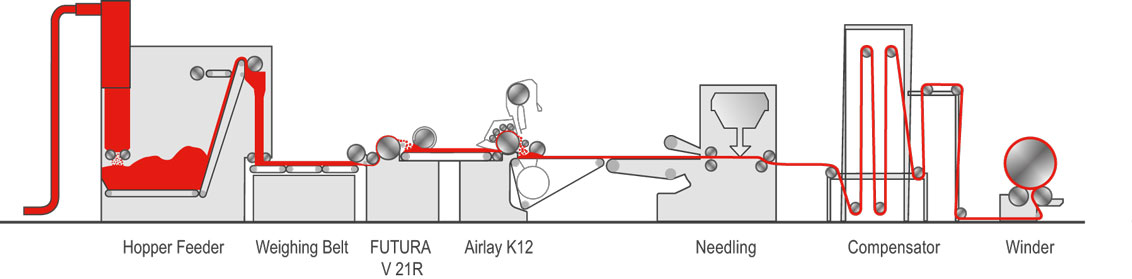

- Product width up to 7 m

- Web product weight range 70 – 1200 gsm

- Polypropylene and Polyester nonwoven Geotextile/ Geosynthetic

- Road and rail building

- Geobags

- Dam, canal and pond lining

- Hydraulic works

- Sewer lines

- Soil stabilisation and reinforcement

- Soil separation

- Drainage

- Landfill

- Filtration

- Sedimentation and erosion control

- Weed control

- Root barriers

- Asphalt overlay

- Impregnation base

- Drainage channel liners