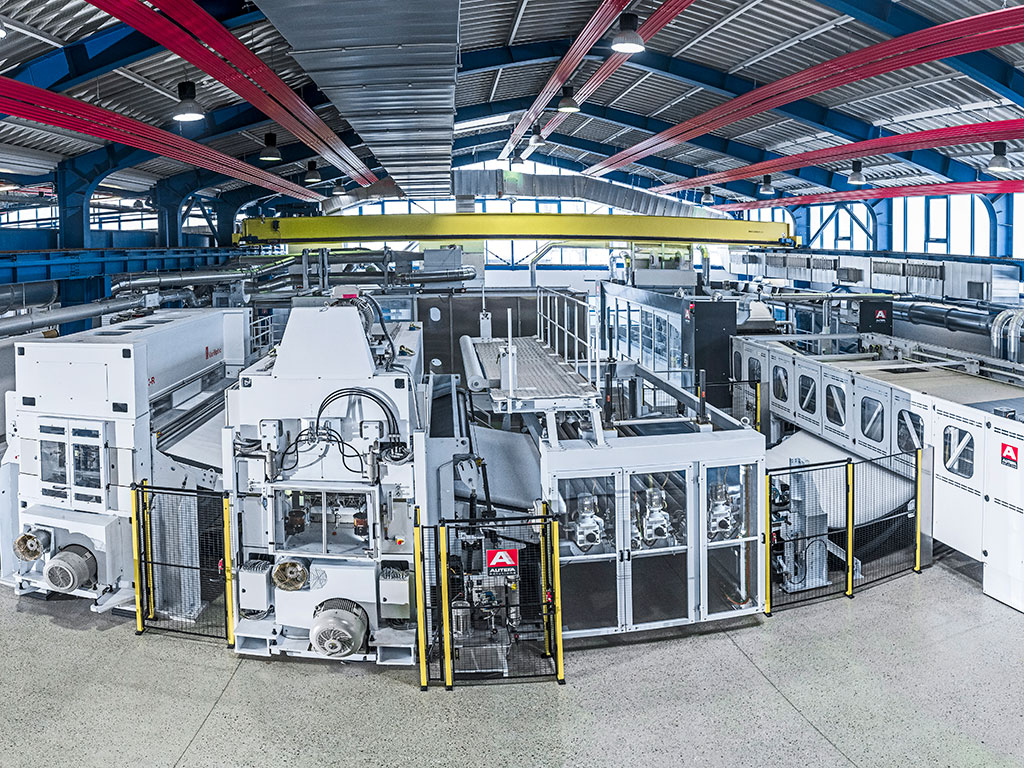

Upgrade Your Nonwoven Production Line with AUTEFA Solutions

Cost-effective retrofits to enhance safety, efficiency, and performance.

Nonwoven production lines are complex and diverse. They can process an extraordinary variety of fibers and materials to produce a wide range of products. With good care and regular maintenance, the machines and equipment have a very long service life. Machines and complete production lines from AUTEFA Solutions and the former AUTEFA in Friedberg (Bavaria, Germany), Fehrer in Linz (Austria), FOR and OCTIR in Biella (Italy) and Strahm Hi-Tex in Switzerland have been in use for decades. We provide our customers with valuable and cost-effective solutions and upgrades that enhance existing systems and allow them to adapt to ever-changing market conditions. Our modifications yield significant improvements in occupational safety, reduce work effort, increase process reliability, and minimize complaints.