LINE CONCEPTS FOR THE PROCESSING OF CARBON FIBERS AND RECYCLED CARBON FIBERS

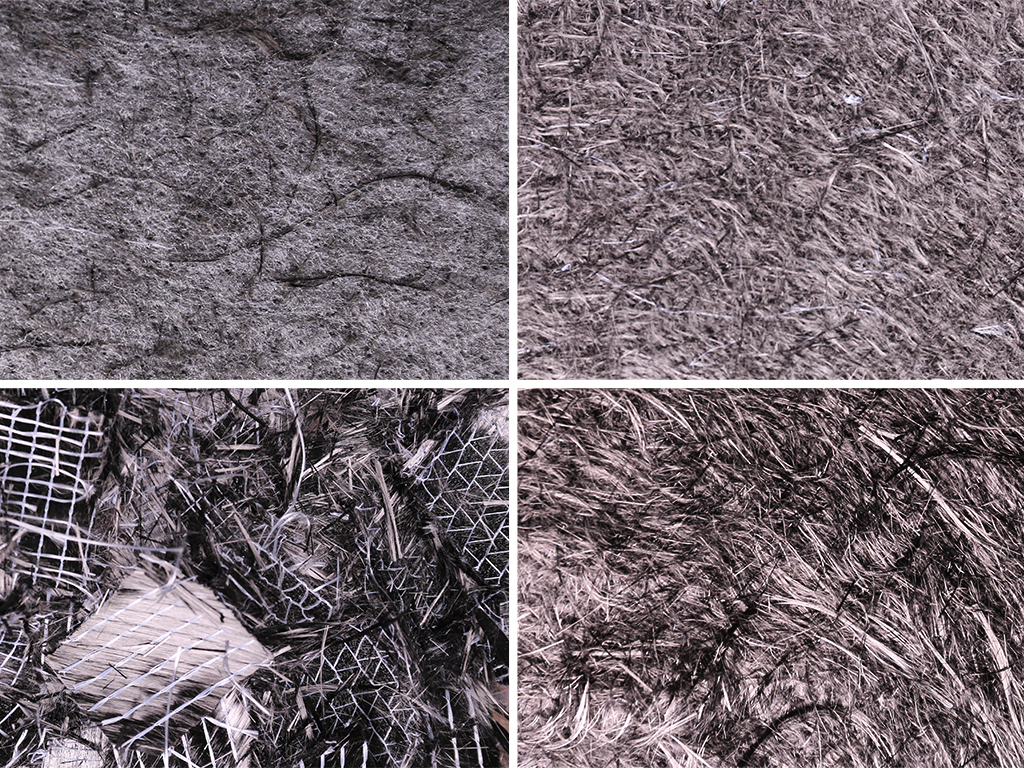

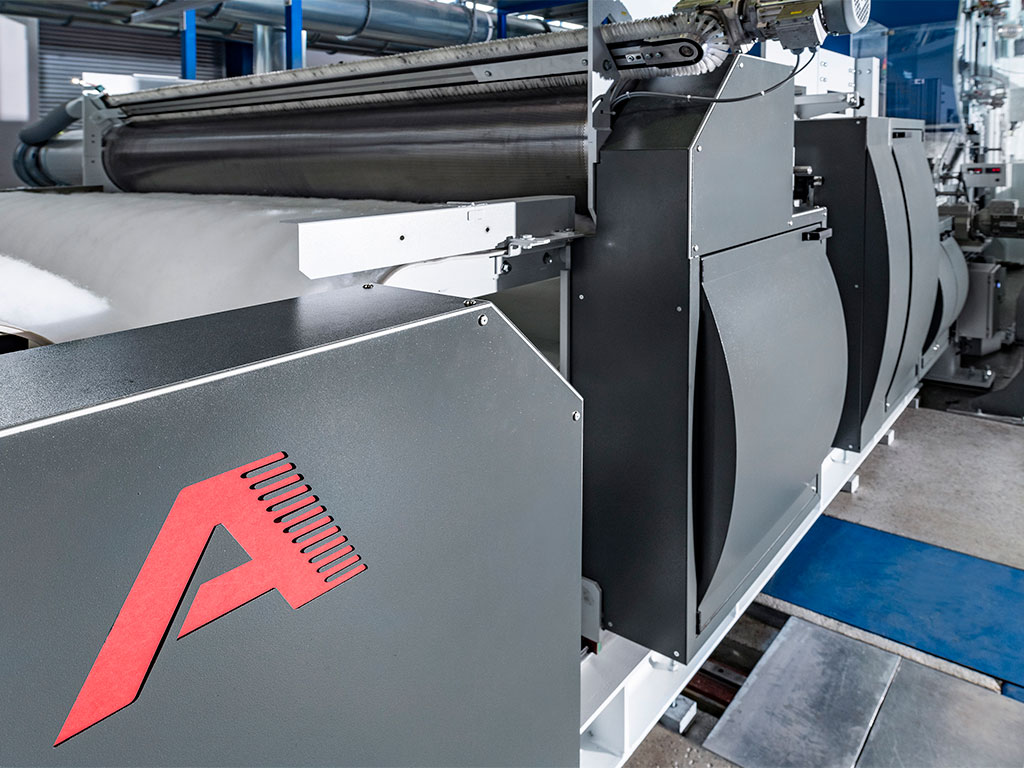

AUTEFA Solutions provides lines for processing carbon fibers and recycled carbon fibers, pure or in blends with a wide variety of organic and inorganic fibers (such as Polypropylene, polyamide, Jute, Hemp, and Flax). Large quantities of recyclable carbon fibers are produced annually in the manufacture of carbon fiber-reinforced components. Added to this quantity are carbon fibers from components that have reached their service life and should be recycled in a reasonable manner. These fibers are a high-value recyclable material. AUTEFA Solutions offers solutions and shows how the carbon fibers can be recycled as nonwovens for industrial use.