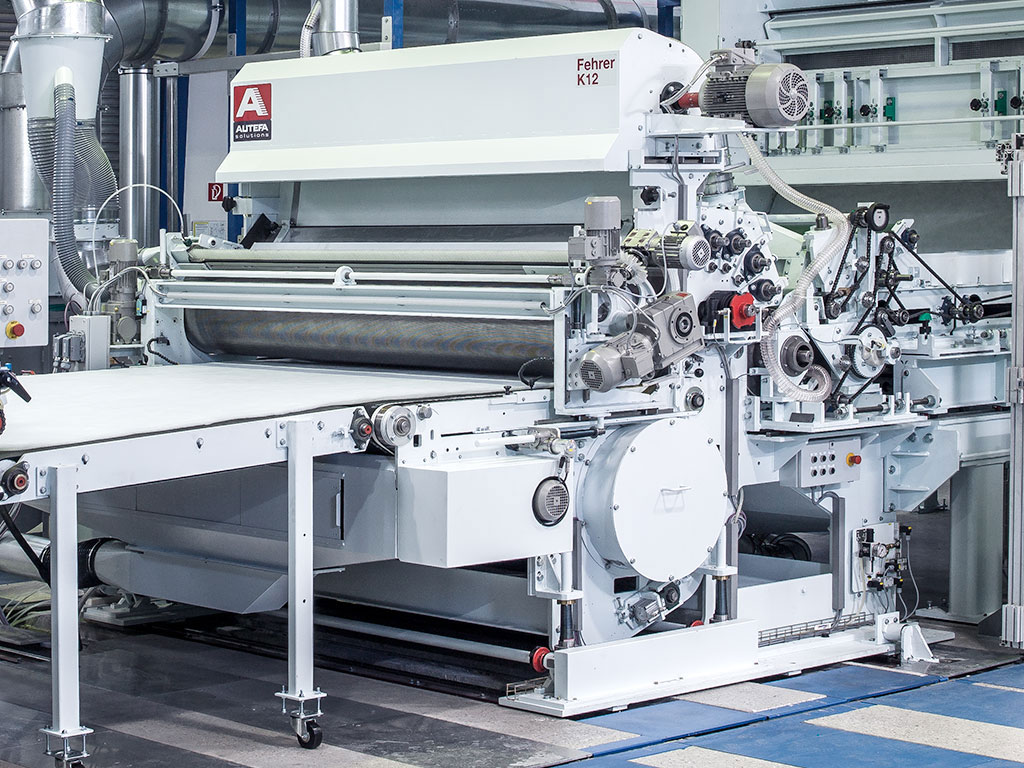

Lines for aerodynamic web forming

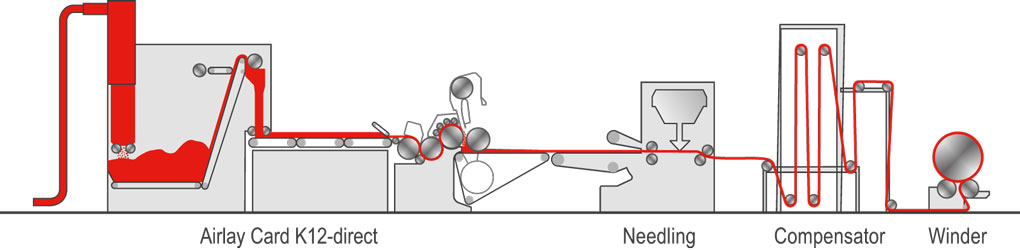

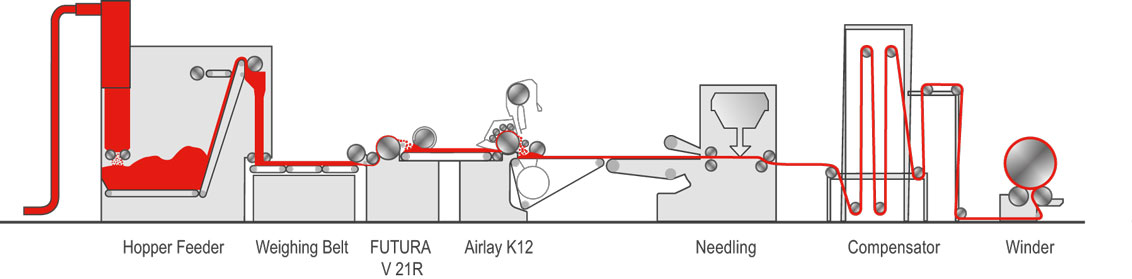

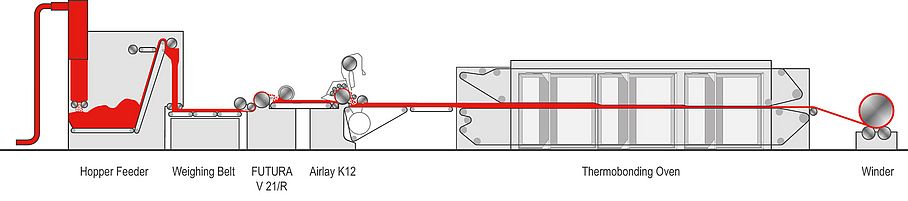

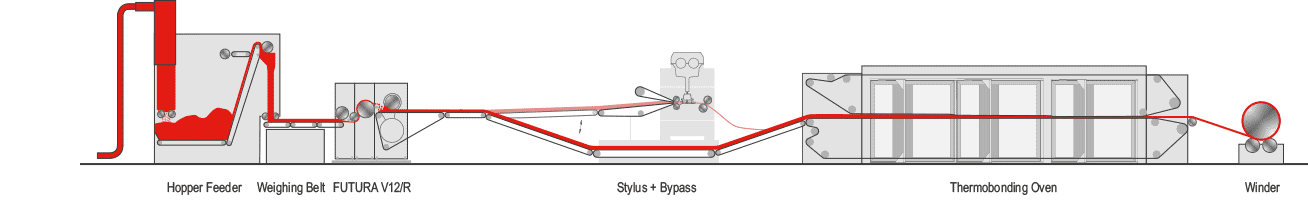

AUTEFA Solutions Airlay random card K 12, in combination with Stylus Needle Loom or HiPerTherm Oven, meet all customer requirements for maximum productivity and constant high quality. Suitable for all kinds of bonding processes such as thermal-, chemical- or needle-bonding.

Airlay line solutions distinguish itself through maximum product quality, economical production and reliability. With worldwide over 500 systems sold, customers taking advantage of the long-standing experience in carding and card feeding technology of F.O.R. and the worldwide acknowledged know-how in aerodynamic web forming of Fehrer K 12.

The FUTURA design enables easy opening and quick access for cleaning and maintenance. The various line components are mounted on a linear guiding system. Due to the modular structure of the individual components, it allows a modular configuration of the machine, tailored to customer requirements. Completed with Needle Punching Machines Stylus and Thermobonding Oven HiPerTherm, AUTEFA Solutions provides aerodynamic web forming lines out of one hand.

- Working widths 1200 – 4200 mm

- High production capacity

- Intensive fiber opening

- Total random 3D web structure and isotropic strength values

- Increased resilience of the web

- The "high-loft" device offers random webs of up to 80 % greater volume

- Suitable for all kinds of bonding processes such as thermal-, chemical- or needle-bonding

- High flexibility with modular structure of the individual components mounted on a linear guiding system

- Electrical and recipe controlled adjustment of deflection tube for homogenous fiber blendings

- Easy opening for fast cleaning and efficient maintenance

- Filter materials

- Automotive felts

- Automotive substrates

- Insulation materials for thermal and acoustic insulation

- Interlinings

- Mattress felts

- Medical and hygiene products

- Blankets (needled)

- Industrial wipes

- Waddings for upholstery and garments

- Web product weight range 80 – 9000 g/m²