媒体

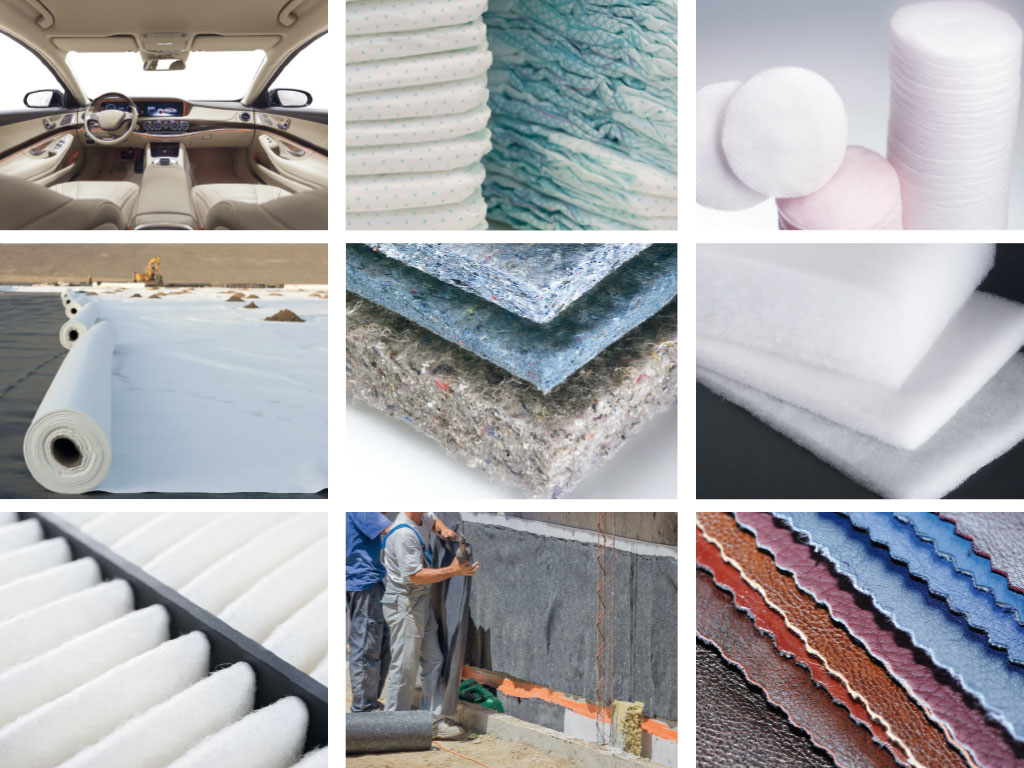

AUTEFA Solutions 是领先的整体解决方案供应商,为梳理-交叉铺网针刺、水刺和热轧非织造布工艺提供交钥匙生产线和设备。除完整成套设备外,AUTEFA Solutions 还提供涵盖安装调试、生产支持以及质量和产能保证在内的全方位工程服务。在本媒体专区,您可以查阅精选文章、新闻稿和项目案例,了解我们在全球非织造布行业的技术实力与客户参考。

与我们联络 germany@autefa.com.

AUTEFA Solutions 是领先的整体解决方案供应商,为梳理-交叉铺网针刺、水刺和热轧非织造布工艺提供交钥匙生产线和设备。除完整成套设备外,AUTEFA Solutions 还提供涵盖安装调试、生产支持以及质量和产能保证在内的全方位工程服务。在本媒体专区,您可以查阅精选文章、新闻稿和项目案例,了解我们在全球非织造布行业的技术实力与客户参考。

与我们联络 germany@autefa.com.

The global filtration nonwovens market is expanding rapidly due to stricter environmental regulations, the demand for cleaner air and water, and advanced automotive and industrial applications. With its StylusONE needle loom technology and a new reference installation comprising seven StylusONE needle looms at Zhejiang Heading Filter Material Co., Ltd. in China, AUTEFA Solutions is underlining its role as a reliable partner for the production of efficient, precise and economical high-performance filter media..

Read the full article in The Texdata Magazine to find out how StylusONE and LineONE support challenging filtration applications around the world.

AUTEFA Solutions will be exhibiting at ITMA Asia + CITME 2025 (28–31 October 2025) at the Singapore Expo, Hall 2, Booth D201, as a leading supplier of complete production solutions. From its three Business Units – Nonwovens, Baling Technology, and Woollen Carding Technology – the company delivers tailor-made machinery. Visitors can look forward to state-of-the-art technologies, proven equipment, and a trade-fair premiere: the presentation of the Stylus ONE needle loom.

AUTEFA Solutions invites all interested visitors to experience the latest developments live. Further details you will find the our latest press release.

![[Translate to Chinese:] 2025_Custoemr Day India Roberto Degrandi [Translate to Chinese:] 2025_Custoemr Day India Roberto Degrandi](/fileadmin/user_upload/Nonwovens/Media/2025_04_customer_day_India__Degrandi_web.jpg)

How can a global technology leader meet the rising demand for high-performance nonwoven solutions in a diverse and rapidly developing market like India? AUTEFA Solutions, a renowned manufacturer of machinery and systems for the nonwovens sector, is taking a strategic approach: innovation, efficiency – and strong local representation. In this exclusive interview, Roberto Degrandi, Regional Sales Director for Woollen, Worsted and Nonwovens Technology, shares valuable insights into AUTEFA’s market strategy and the company’s latest milestone: a new partnership with Batliboi, one of India’s most established industrial solution providers. Operating in major hubs like Delhi, Mumbai, Ludhiana, Tirupur, and Kolkata, Batliboi now represents AUTEFA across the country – enabling closer customer support and stronger market coverage.

Read the full interview to discover how AUTEFA Solutions is shaping the future of nonwoven production – with smart solutions, market foresight, and local strength.

![[Translate to Chinese:] 2025 AUTEFA customer day India, Roberto Degrandi, Amrish Gupta and Team Batliboi [Translate to Chinese:] 2025 AUTEFA customer day India, Roberto Degrandi, Amrish Gupta and Team Batliboi](/fileadmin/user_upload/Nonwovens/Media/2025_04_customer_day_India_Degrandi_Gupta_agent_Batliboi_web.jpg)

AUTEFA Solutions, together with its valued partner Batliboi Ltd., successfully hosted the "Nonwovens Industry Meet" at the Radisson Blu Hotel in Mumbai on April 9, 2025. The event welcomed a large number of professionals from the Indian nonwovens industry to exchange ideas and explore cutting-edge solutions in nonwoven production. The event focused on showcasing AUTEFA’s advanced technologies, including carded-crosslapped needle punching lines, airlay systems, spunlace, and thermobonding solutions. Attendees had the opportunity to learn how AUTEFA’s technologies help manufacturers achieve high productivity, operational flexibility, and significant energy savings. “We are truly pleased with the strong turnout and the engaging conversations we had throughout the day,” said Roberto Degrandi, Regional Sales Director at AUTEFA Solutions. Alongside Amrish Kumar Gupta, Sales Manager India, he led the presentation of AUTEFA’s latest developments tailored to the growing demands of the Indian market.

Sustainable Airlay Solutions for Natural Fibers

With recycling and sustainability driving industry trends, Airlay applications using natural fibers such as hemp, jute, flax, and coconut are gaining significance. Backed by decades of expertise, AUTEFA’s Airlay technology ensures exceptional quality and reliability. The FUTURA V12/R web forming machine provides a compact, cost-efficient solution for processing natural fibers and textile waste. Designed specifically for recycled materials, shoddy, and natural fiber production, the V12/R delivers high-performance technology at moderate costs.

Leadership in Needle Punch and Crosslapping Technology

Carded, crosslapped, and needle-punched lines remain the most widely used processes for nonwoven production, offering versatility and efficiency. With Fehrer Needlepunch technology, AUTEFA Solutions is a recognized market leader in needle looms and crosslappers, known for exceptional quality, robust machine design, and long machine lifetime. Combined with outstanding technical support and continuous innovation, AUTEFA Solutions ensures maximum efficiency and superior results for nonwoven manufacturers.

André Imhof, CEO of AUTEFA Solutions Austria, emphasizes: " Sustainability is an important aspect of our commitment. We have also noticed that interest in economical production lines for nonwovens manufacturing continues to grow. We are also seeing a strong trend towards digital transformation, where digital technologies are being used to increase production efficiency and quality. Upgrades and retrofits are also crucial to further improve product quality, operational safety and environmental sustainability.”

The Airlay V21/R - K12 from AUTEFA Solutions offers a versatile solution for processing natural, sustainable and recyclable fibers. Airlay systems offer the highest product quality, efficiency and reliability by opening the material down to the individual fiber, allowing high flexibility in fiber selection.

AUTEFA Solutions is proud to have supplied complete needle punching geotextile lines to Suhail Industries, a leading holding group in Qatar. By using state-of-the-art technology, Suhail Industries demonstrates its ability to adapt to the ever growing market requirements and to react promptly and flexibly to individual customer needs. Driven by the increasing demand in recent years, the decision to invest in a new geotextile production line underlines the commitment to meet the growing demand for geotextiles in Qatar and international markets.

The selection of AUTEFA Solutions as a partner reflects their extensive experience and market leadership. AUTEFA Solutions, a leading supplier of turnkey nonwoven lines and machines. AUTEFA Solutions boasts a rich and storied history that spans several years, marked by a relentless pursuit of excellence and innovation in the field of nonwovens technology. Established as a company dedicated to providing cutting-edge solutions for the textile industry, AUTEFA Solutions has evolved into a global leader in turn-key nonwovens lines and machines. The company's comprehensive offerings cover a wide spectrum of applications, including lines for the production geotextiles, ensuring that it remains a versatile and integral player in various sectors.

The production of papermaking felts is one of the most complex processes in the nonwovens industry. It combines the highest quality standards with unusual requirements for fabric width and desired basis weight. Papermaking felts are used in the drying stage of the papermaking process and play a crucial role in determining the surface quality of the final product.

The production of papermaking felts requires the highest precision, especially in the needling process over the entire working width. AUTEFA Solutions achieves this with ingeniously designed rigid steel frames that allow minimal vibration even at working widths of up to 17 meters.

ITMA 2023 was set to be a transformative event in the world of textiles. Under the overarching theme of 'Transforming the World of Textiles', ITMA 2023 showcased the latest advances and trends in the industry with a particular focus on four key sub-themes: advanced materials, automation and the digital future, innovative technologies, and sustainability and the circular economy. The AUTEFA Solutions team was pleased to see the great interest in our machines and technologies.

More information

As sustainability becomes an increasingly important consideration in the fashion industry, the demand for textile circularity is growing significantly as consumers and companies alike seek solutions to recycle fast fashion. In response to this trend, AUTEFA Solutions offers innovative solutions designed to process and reuse various types of fibers, including reclaimed, natural and man-made materials. The compact and economical machine for processing all natural fibers such as coir, sisal, jute, hemp and cotton as well as animal hair/wool and textile waste is the Airlay V12/R Aerodynamic Web Forming Machine. Fed by a hopper feeder, the Airlay V12/R is capable of producing nonwovens in a weight range of 400 - 8000 gsm.

At INDEX in Geneva from April 18-21, 2023, AUTEFA Solutions will showcase its latest technical developments in the field of nonwoven production technology. The focus is not only on classic mechanical engineering with its ambitions for higher-faster-further, but also on the protection of resources and on excellent, individual customer support within the scope of the "Assessment for Thermal Systems".

Water - the source of life - is the basis of the spunlace process that AUTEFA has been actively developing for years. The company’s wide product range offers cutting-edge technology for web forming as well as hydroentanglement and finally, drying of the produced nonwovens.

During Techtextil, visitors will experience the economic and technical advantages of AUTEFA Solutions as a full line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace, and thermobonding lines. AUTEFA Solutions is committed to technology that is both innovative and sustainable.

More information

Autefa宣布将为Confidence Infrastructure 公司提供两条成套的针刺土工布生产线,该公司是孟加拉国领先的工程解决方案供应商之一。拥有尖端的技术,Confidence Infrastructure 公司能够适应不断增长的市场需求,并针对个体客户做出迅速而灵活的反应。由于过去几年不断增长的需求,公司决定再投资两条新的土工布生产线。

该项目供货范围包括从纤维开松混合、双道夫梳理、配置WebMax控制的交叉铺网机Topliner、针刺机Stylus NL到卷绕机的成套设备。Confidence Infrastructure公司将生产300-600gsm的聚丙烯和聚酯非织造土工布,最大幅宽可达4.2米,生产的大部分产品将用于防腐控制的土工布袋。 更多信息

非织造布行业期待着在即将举行的SINCE上海国际非织造材料展览会上庆祝技术和商业领域的进步。在疫情期间,一些产品在全球市场的应用——尤其是用于卫生和消毒湿巾的水刺产品——急剧增长。奥特发公司已经为满足这种“巨大需求”的延续性做好准备,其最新的系统将在展会上展示。

奥特发的首席运营官Marco Fano说:“我们独特的成网技术很好地满足了客户目前的需求,我们看到未来订单持续上升的趋势,尤其是在梳理和铺网的方案组合上。我们先进的水刺制造系统能够提供高标准的质量和性能,具有最重要的快速投资回报的优势。” 更多信息