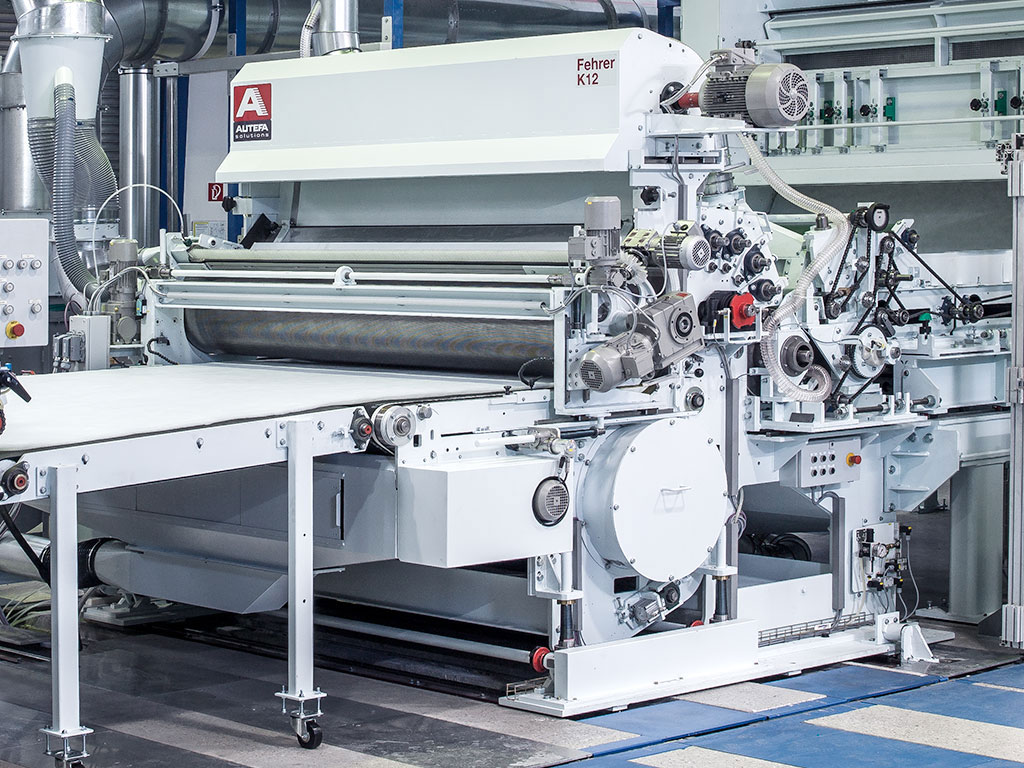

Airlay - Aerodynamic web forming process

For aerodynamic web forming, random cards from AUTEFA Solutions utilize the aerodynamic principle which results in three-dimensional fiber orientation and total randomization, enabling isotropic web properties. Airlay line solutions distinguish itself through maximum product quality, economical production, and reliability. The random carding process stands for an improved MD:CD ratio and a three-dimensional web structure. During the process, the fiber material could be opened up to a single fiber, this enables a high versatility regarding fiber choice. The FUTURA design enables easy opening and quick access for cleaning and maintenance. The various line components are mounted on a linear guiding system. Due to the modular structure of the individual components, it allows a modular configuration of the machine, tailored to customer requirements. Completed with Needle Punching Machines Stylus and Thermobonding Oven HiPerTherm, AUTEFA Solutions provides aerodynamic web forming lines out of one hand.