i-POINT Simulation tool for needle board pattern

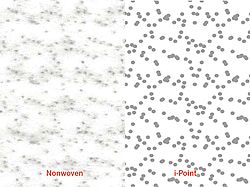

An improved and even surface quality has been set as key target by our customers. Therefore, AUTEFA Solutions offers the service of a customized needle board pattern. The i-Point needling simulation tool increases the capacity and the quality of needlepunched fabrics. The development of new needle patterns and the evaluation of surface quality is much more effective and economic with the i- Point software technology. It creates a layout of stripper and bed plate including the elliptic needling (Variliptic). This customized design of needle pattern, which takes also draft and shrinkage into consideration, reduces the process optimization time on customer site. AUTEFA Solutions needlepunch lines produce an even and homogenous fabric with outstanding technical performance in terms of tensile strength and evenness (MD/CD ratio).

Main characteristic features:

- Development of new needle boards

- Simulation of new needle boards

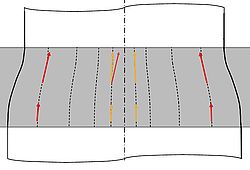

- Manual and automatic optimization of needle pattern for desired needle densities

- Optimization of up to three different production points

- Display of optimized areas for advance per stroke at a glance

- Identification of individual needles from penetration pattern

Advantages:

- Worldwide unique technology

- Automatic layout of stripper and bed plate including elliptic needling (Variliptic)

- Less trials for process optimization

- Customized solution of needle pattern with consideration of draft and shrinkage

- Simulation of multiple needle boards

- Objective assessment criteria for needle patterns

- Multi-target optimization between line capacity and product quality

- Optimized and customized line layout

CONTACT

AUTEFA Solutions Austria GmbH

Wegscheider Strasse 15

4021 Linz . Austria

T: +43 732 3739 0

austria@autefa.com