Needle Punching Technology- Needle Looms

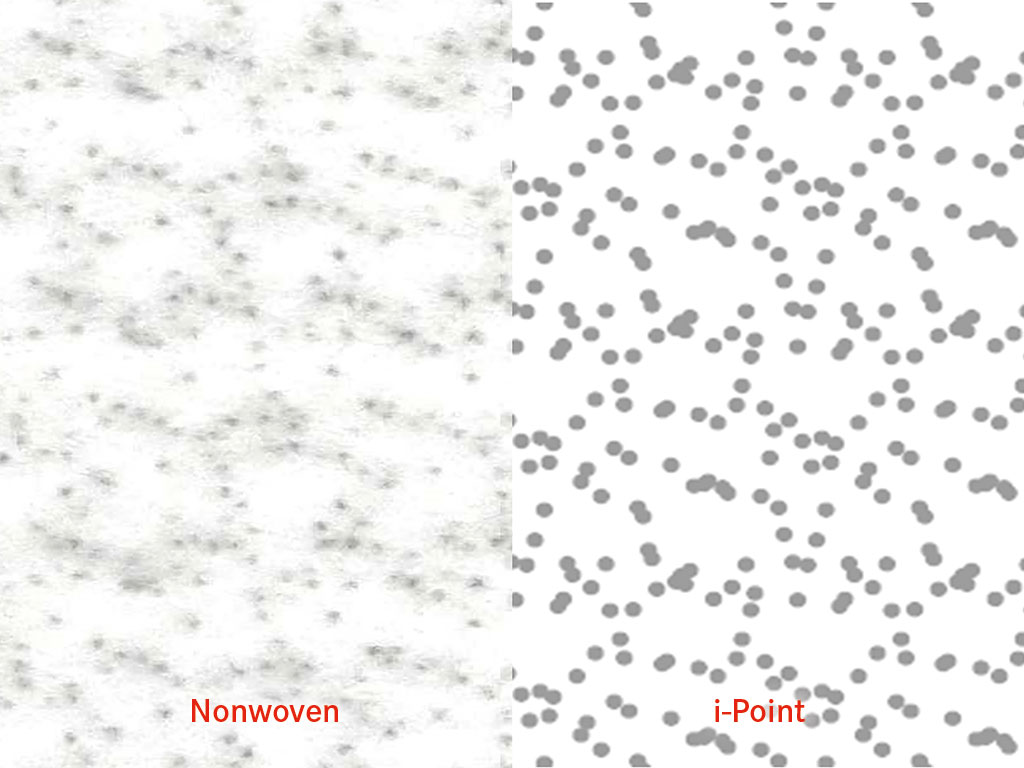

Needle punching machines, or needle looms, are essential in the production of nonwovens. Nonwovens are mechanically bonded by needling. The needles punch vertically into and out of the material, interlocking the fibers by using the barbs on the needles. The felt is driven through the needle zone by the drive of the feed rollers.

The product range of AUTEFA Solutions includes single and double board needlelooms, tandem needlelooms, velour, structuring and patterning needlelooms based on the Needleloom Stylus NL drive concept series and the Needleloom Stylus VARILIPTIC drive concept. Needlelooms from AUTEFA Solutions combine Fehrer's know-how and many years of experience with the latest technology and offer optimum solutions for every kind of needling requirement, as single machines or integrated in complete lines.