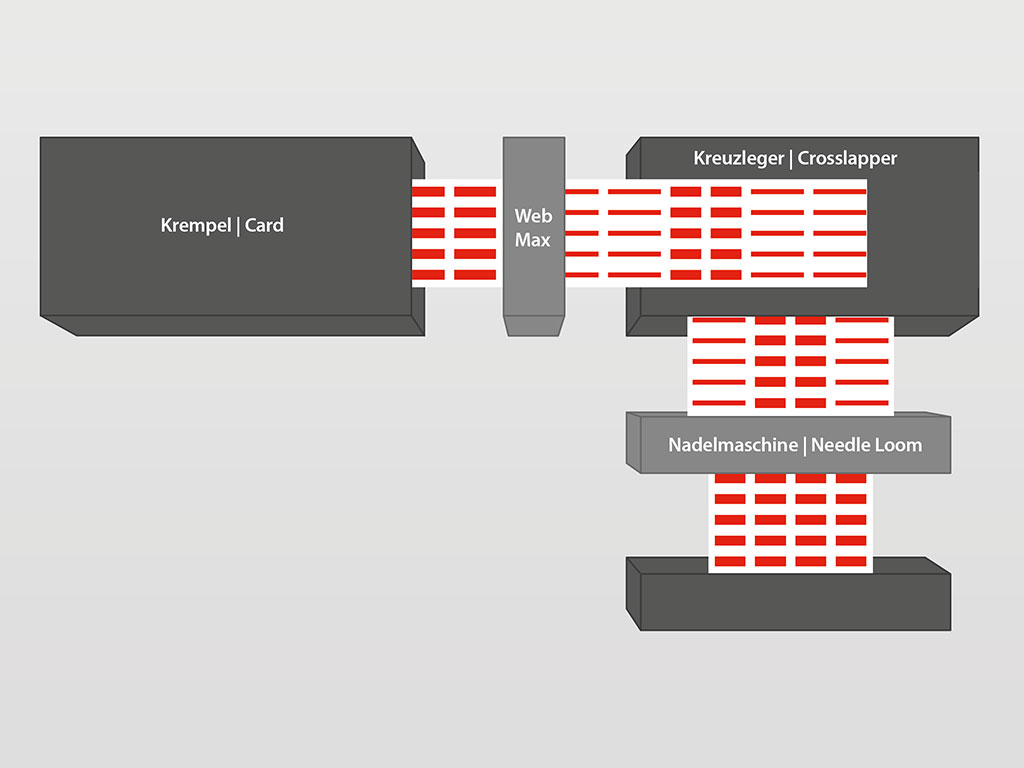

Crosslapper for Nonwovens – Crosslapping Technology

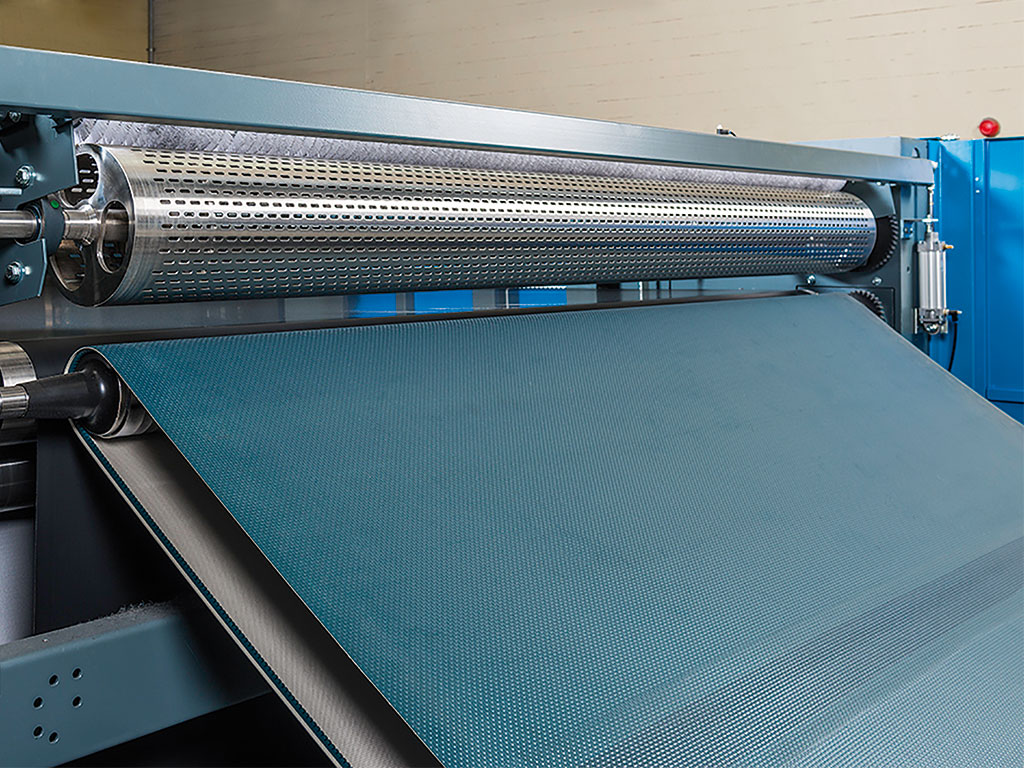

A crosslapper takes the carded web from the carding machine and lays it in multiple layers. Weight accuracy in lapped and bonded webs is the most important quality feature for a nonwoven installation. AUTEFA Solutions crosslappers are characterized by high infeed speeds and precise weight distribution. Crosslappers take up the carded web coming from the carding machine with constant speed and gently bring it to the delivery belt. Since decades, AUTEFA Solutions delivers customers outstanding crosslapping technology.