Filling systems and lines for glass bottles

Glass bottles offer advantages for the beverage industry and filling companies. Glass bottles offer a high standard of hygiene and a long shelf life for the end product. They also stand for sustainability and are an essential part of the circular/ recycling economy.

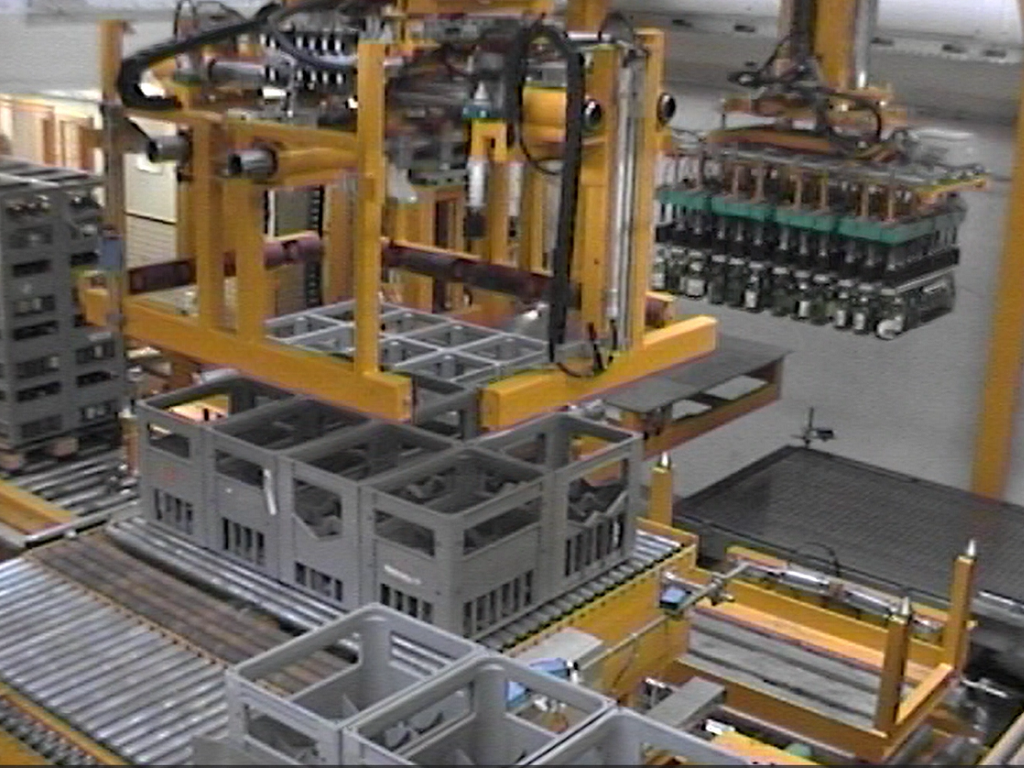

AUTEFA Solutions supplies complete lines for filling companies such as breweries, wine bottlers and juice bottlers - from material receiving to fully automated storage systems with integrated dispatch provision. Depending on requirements, multi-axis high-performance machines are used for depalletizing, packaging, palletizing or stacking. Fully automated gripper heads and feeders streamline the process by significantly reducing set-up times, among other things. In the case of customer-specific requirements or special space conditions, the machine is adapted to povide an optimum solution for the respective application.

Glass bottles are used in many industries, particularly where the material properties of glass are advantageous. Here are some of the main industries where glass bottles are used:

- Food and Beverage Industry

- Wine and Spirits: Glass bottles are the preferred packaging material for wine, beer, whiskey, vodka, and other spirits because they are inert and do not affect the taste.

- Soft Drinks and Juices: High-quality juices and soft drinks are often bottled in glass to preserve freshness and taste.

- Oils and Vinegars: Edible oils (e.g., olive oil) and vinegars are frequently packaged in glass bottles as glass protects the product from oxidation.

- Pharmaceutical Industry

- Medications: Many liquid medications, syrups, injection solutions, and vaccines are packaged in glass bottles to ensure their stability and purity.

- Laboratory Glass: Glass bottles are used in laboratories for storing reagents and chemicals because they do not react with most substances.

- Cosmetics and Personal Care Industry

- Perfumes and Essential Oils: High-quality perfumes and essential oils are often bottled in glass to protect the aroma and prevent the volatile components from escaping.

- Cosmetic Products: Creams, lotions, and serums are frequently offered in glass containers to ensure the quality and durability of the products.

- Canned Food Industry

- Jams and Preserves: Glass is a popular material for packaging jams, preserves, and honey because it protects the contents from contamination.

- Pickled Vegetables and Fruits: Glass containers are used for preserving pickled vegetables and fruits to maintain freshness and flavor.

- Dairy Industry

- Milk and Dairy Products: In some regions and for certain markets, milk is bottled in glass to emphasize the freshness and quality of the product.

- Chemical Industry

- Solvents and Reagents: Glass bottles are essential for packaging and storing many chemical reagents and solvents due to their high chemical resistance.

- Perfume Production: High-purity solvents and fragrances are often stored in glass bottles to avoid contamination.

- Homebrewing and Hobby Brewing

- Beer and Wine: Homebrewers and small breweries often use glass bottles for bottling their products to emphasize authenticity and quality.