Filling Systems and Lines for Cans

Cans, both standard and lightweight, are a popular packaging solution in many industries because of their versatility and advantages: they offer long shelf life by effectively protecting against light, air and moisture. Without the use of preservatives, the contents remain fresh thanks to sterilization and sealing. Unlike glass, beverage cans are impact and pressure resistant and 100% recyclable. They can be used for a wide range of applications, from food to cosmetics.

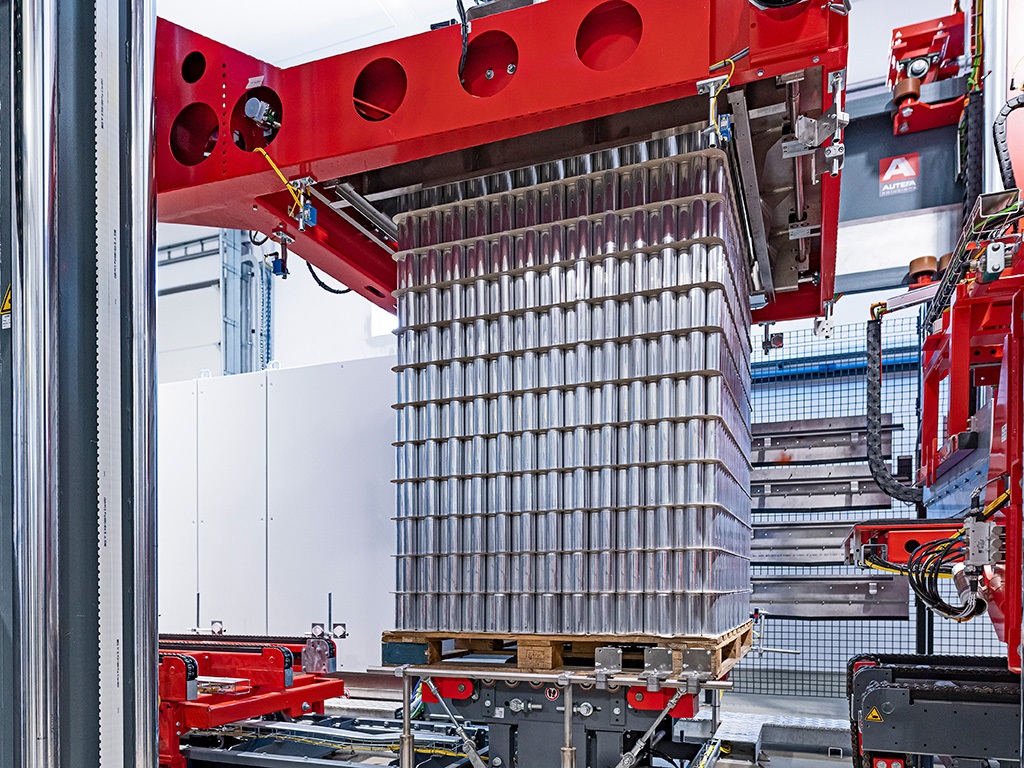

AUTEFA Solutions supplies complete lines for bottling plants such as dairies, soft drinks, mixed drinks or other liquid products - from material reception to fully automatic storage systems with integrated dispatch preparation. Depending on the requirements, multi-axis high-performance machines are used for depalletizing, packaging, palletizing or stacking. Fully automatically adjustable gripper heads and feeders streamline the process by significantly reducing setup times. In the case of customer-specific requirements or special space conditions, the machine is adapted to provide an optimum solution for the application in question.

Cans are used in a variety of industries as they offer a practical, durable, and often cost-effective solution for packaging and storing various products. Here are some of the key industries in which cans are used:

- Food and Beverage Industry:

- Food Cans: Fruit, vegetables, soups, meat products, and ready meals.

- Beverages: Beer, sodas, energy drinks, juices, and other non-alcoholic beverages.

- Specialty Foods: Baby food, pet food, seafood (e.g., tuna, sardines).

- Cosmetics and Personal Care Industry:

- Hair Care Products: Hair sprays and dry shampoos.

- Deodorants and Antiperspirants.

- Shaving Foams and Gels.

- Pharmaceutical and Medical Industry:

- Medical Aerosols: Asthma inhalers, nasal sprays.

- Nutritional and Dietary Supplements.

- Chemical Industry:

- Paints and Coatings: Spray paints, lacquers.

- Cleaning and Maintenance Products: Disinfectants, shoe care products, polishes.

- Insect Sprays and Pest Control Products.

- Technical and Industrial Applications:

- Lubricants: Lubricating oils and greases in spray cans.

- Adhesives and Sealants.

- Compressed Air in Cans: For cleaning electronics and hard-to-reach places.

- Household Goods:

- Food Storage: Cans for dry foods such as coffee, tea, and spices.

- Cleaning Products: Furniture polish, carpet cleaners.

- Art and Craft:

- Artists' Paints: Spray paints for graffiti and other artistic applications.

- Craft and DIY Projects: Lacquers and spray adhesives.