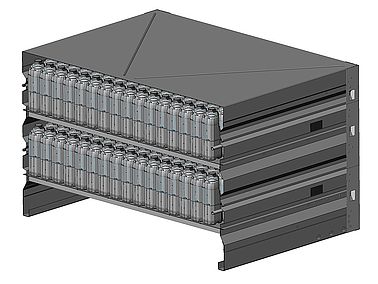

Buffer Systems - Intermediate Bottle Storage System (IBSS)

For In-house plants AUTEFA Solutions offers revolutionary buffer systems between blow moulding and filling for plastic bottles. After blowing the bottles are stored in metal trays which are stacked on top of each other. Those stacks are transported to the storage area and can be delivered to the filler flexibly, whenever the product is required for filling.

Due to the modular design concept of the patented tray loader system which has already been installed at well-known companies all over the world, buffering times from a few minutes up to several days are possible and this with considerably reduced space requirement compared to common installations. By this innovative system differences in production times, efficiencies and operational capacities can be balanced. Thus, a so far unknown flexibility in the production process is made available for the customer. The system handles the product so gentle, that even the lightest light-weight bottles can be stored without any quality losses.

Highlights:

- Buffer capacity from 5min up to several days

- Big variety of products in buffer system possible (> 150)

- No unscrambling and orientation required

- Balancing of speeds, production schedules, availabilities, change over times,…

- No consumable materials

- Low footprint due to satellite storage systems

- Fully automatic handling and change over

- Modular design concept with buffer capacity from one stack to several thousand stacks

- Redundant machines (optional)

- Tracking of all relevant production parameters in a Database

Video:

CONTACT

AUTEFA Solutions Germany GmbH

Paul-Lenz-Str. 1

86316 Friedberg . Germany

T: +49 821 2608 0

germany@autefa.com