Efficient and safe storage of recycling bales and waste bales

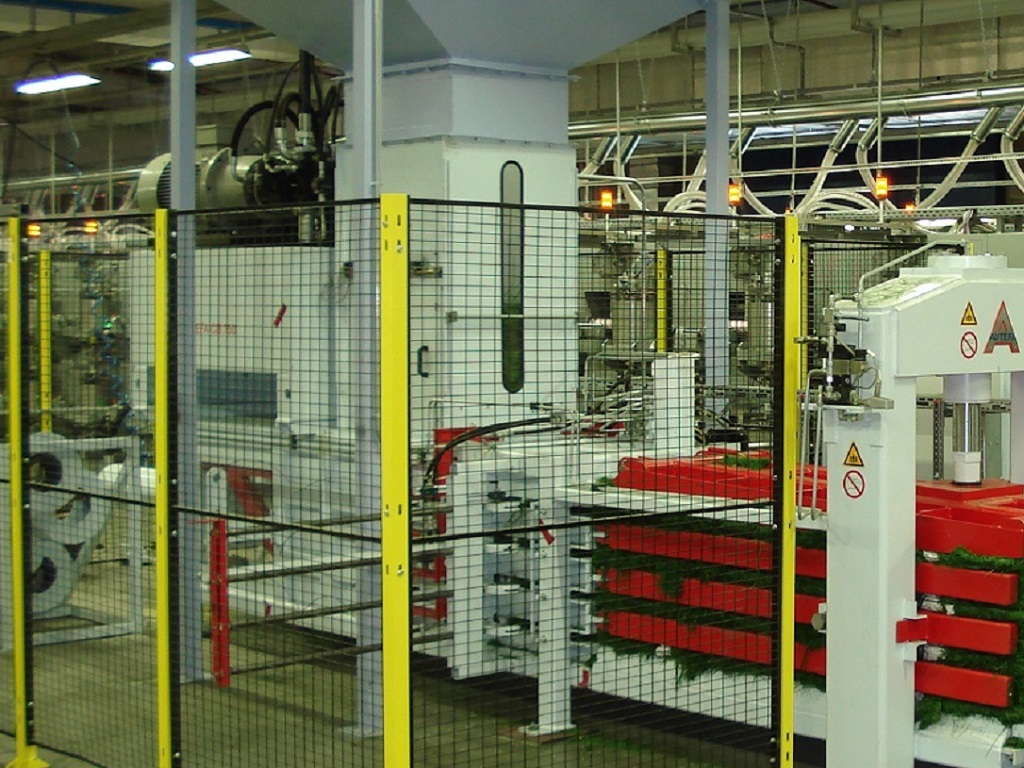

With the BSR Bale Storage Robot, we offer innovative block storage systems.

AUTEFA Solutions understands the diverse challenges of the recycling industry and offers customized solutions to optimize your storage needs. Our focus is on providing first- class block storage systems that save space, increase efficiency and ensure sustainable storage. As a leading supplier of fully automated baling and wrapping systems, AUTEFA Solutions offers state-of-the-art machines and line solutions that cover the entire process from material handling to storage of the finished baled, wrapped and strapped bales in specially designed block storage facilities.

Increase your efficiency and safety with our automatic block storage system for recycling and waste bales. At the heart of the system is the BSR Bale Storage Robot. With limited manpower and increasing demands on waste management, it is more important than ever to rely on innovative solutions. Our automated bale storage system not only offers significant labor savings, but also minimizes the risk of accidents through precise automation. Mix-ups and unnecessary logistical problems are a thing of the past - our solution guarantees optimized logistics and safe storage of your bales.

- Plastic packaging:

- Plastic bottles (e.g. soft drink, soda and shampoo bottles)

- Plastic bags and sacks

- Food packaging such as yogurt cups and meat packaging

- Metal packaging:

- Aluminum cans

- Steel cans

- Composite packaging:

- Beverage cartons (Tetra Paks) made from different materials such as paperboard, plastic and aluminum

- Paper packaging:

- Paperboard packaging

- Paper food packaging

- Textile waste:

- Production residues

- Used textiles