Advanced Spunlace lines for a growing market

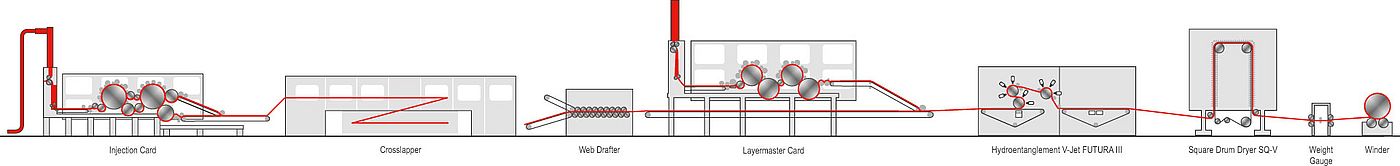

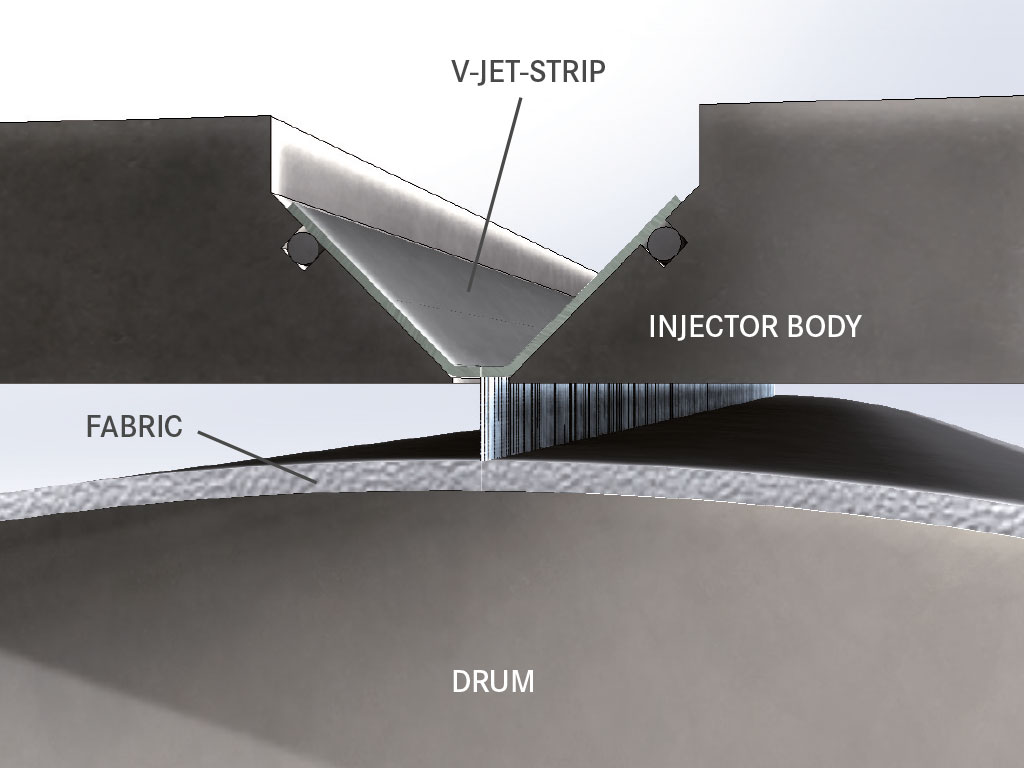

AUTEFA Solutions offers complete production lines for the production of Spunlace nonwovens products, either in a direct or crosslapped configuration. The web forming process, consisting of the unique Injection Card and Crosslapper Topliner CL 4006 SL, is the key for high and consistent nonwoven fabric quality. With the Hydroentanglement Machine V-Jet FUTURA and the Square Drum Dryer SQ-V, AUTEFA Solutions has developed an advanced and unique technology with special focus on reducing energy consumption. During the process of hydroentangling, the carded fibers are bonded by means of jets with high pressurized water entangling the fibers with each other and consolidating the web.

- Delivery speed up to 300 m/min

- Working widths: up to 3.6 m

- Number of spunlace drums: 3

- Number of entanglement injectors: up to 11

- Raw material range: beside the classical CV, PET,LY hardly any limitations, check with our specialists

- Product structure: plain, perforated or structured

- Lower energy consumption (kWh/kg)

- Highest productivity with Injection Card technology

- Best nonwoven fabric quality with Topliner CL4006CL

- EnRec Systems for heat recovery in drying process

- Full line solution out of one hand featuring clear responsibilities

- One - stop-shop for machines and spare parts

- Technology support from bale to fabric

- In house production scale labline for application support

- Web product weight range 20 - 1000 gsm

- Wipes for: hygiene, medical, institutional and industrial applications

- Medical applications like surgical gowns, wound cover, etc.

- Geotextiles

- Filtration

- Single use houshold goods (bed sheeds, napkin, table cloth, etc.)

- Interlinings

- Wall covers

- Artificial leather, vegan leather