Innovation & high performance

AUTEFA Solutions is at the forefront of textile innovation, specializing in high quality carding sets for fine and extra fine wool, cashmere and silk. With the growing demand for luxury products, the gap between lower and higher quality products is widening. "Luxury products are easier to sell and the margins are better. We see that the retail consumer would rather invest in one quality garment than three or four cheap products that are quickly discarded. So the need for better quality machines is a prerequisite to achieve higher quality products," says Roberto Degrandi, our new Regional Sales Director for Nonwovens, Wool and Worsted.

AUTEFA's machines excel in processing delicate fibers such as wool, mohair, alpaca and cashmere. "Our cards deliver excellent quality results. Our machines are gentler on these finer fibers and are preferred by manufacturers who work with very fine microns. Speed is not everything! Faster is not always better," adds Roberto. Discover how our advanced machinery ensures superior fiber control, better yarn quality and greater production efficiency. Read the full article!

AUTEFA Solutions step up for Cashmere

There was a marked increase in demand for wool spinning machinery at the end of 2022, says Giacomo Meucci of AUTEFA in Italy. ‘We continue to receive enquiries from many parts of the world including the UK. And as China re-enters the international market past Covid we expect this will add additional demand. Giacomo Meucci further commented that ‘most European and Chinese wool manufacturing is now concentrating on high- end production for the luxury market – and of course, this ideally requires the best machinery to achieve quality yarn outcome’.

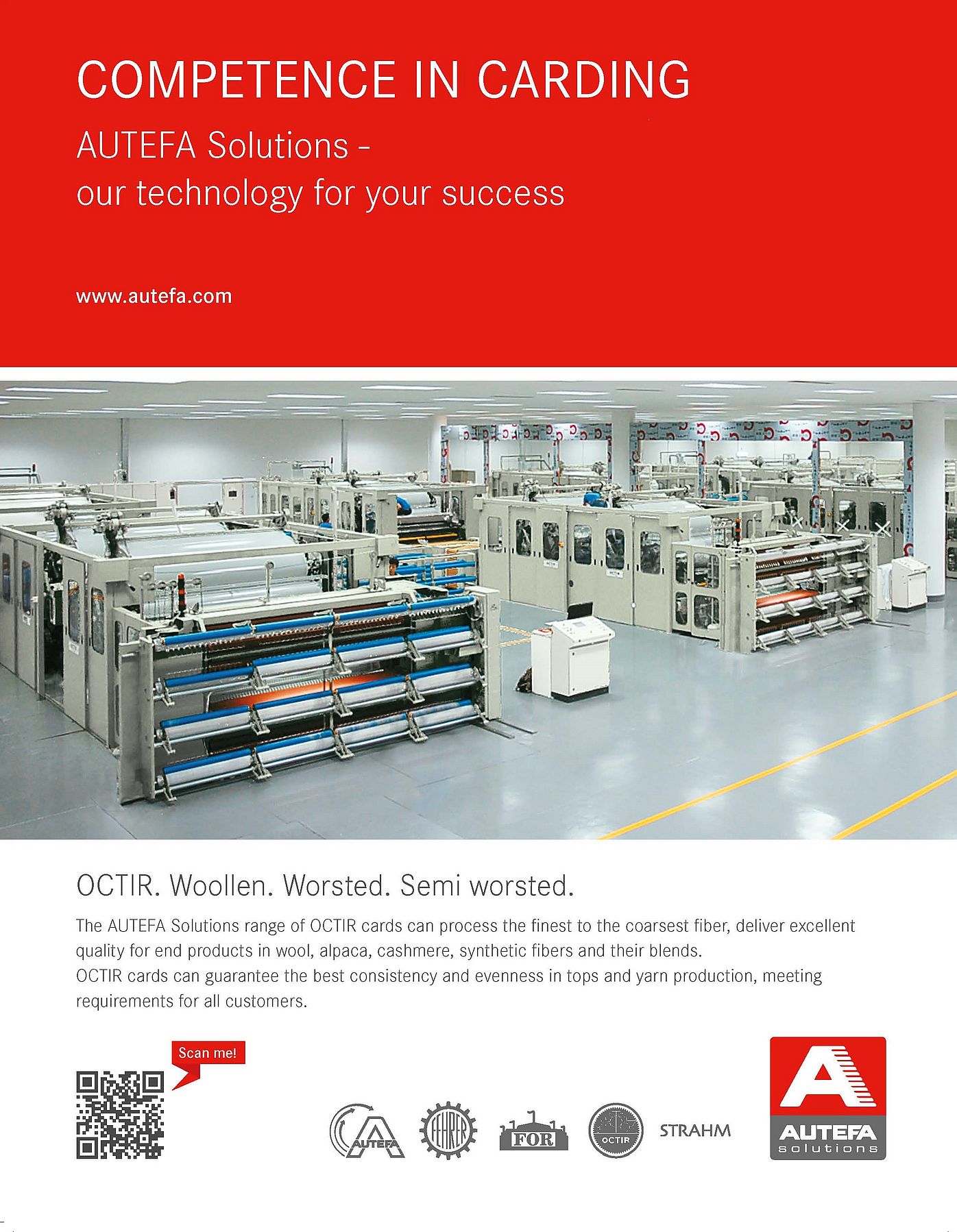

AUTEFA Solutions manufacturers OCTIR woollen carding sets for processing fine and extra fine wool, cashmere and silk, for high quality weaving and knitting yarns. Its product range includes carding sets for processing standard wool and synthetic fibers for carpet and blanket yarns, as well as worsted cards for processing wool, mohair, angora, cashmere, synthetic fibers, and silk for high quality weaving and knitting yarns.

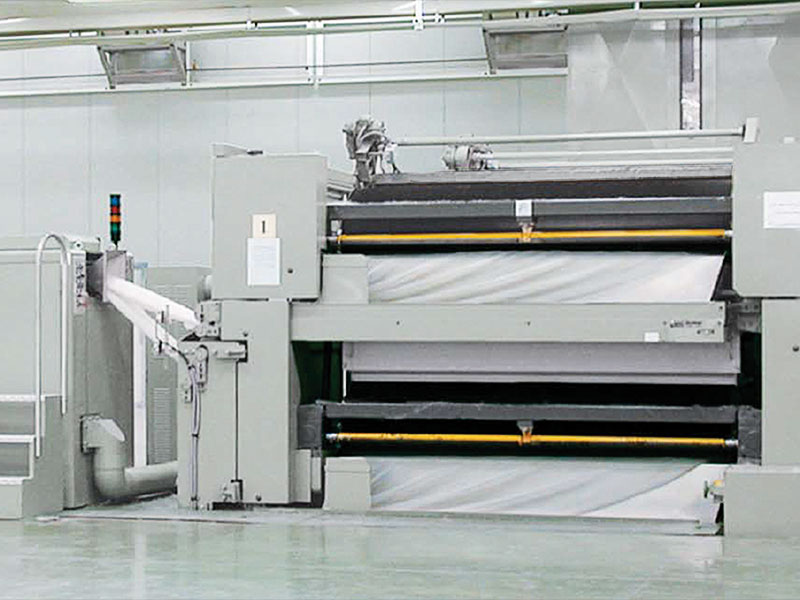

AUTEFA Solutions woollen carding sets enable excellent fiber control, producing a yarn with greater evenness and better CV and Uster values. These cards provide a more simplified opening of the card cover and increased throughput and blending action. A control panel with touchscreen allows easy management of all functions including fault messages. Side doors without rails on the floor create quick and easy access to card parts for cleaning and maintenance. Read the full article

OCTIR Cards for finer microns

‘As good as our old machines are they cannot perform to the same level and produce the quality of products in demand today. To stay competitive, textile manufacturers must use the latest textile machinery. We recently installed a new woollen card at KAPLANLAR TEKSTİL in Turkey. This company uses the finest lambswool, cashmere, alpaca, mohair, cotton, silk and angora fibres for its premium products. The use of fully automated machinery ensures high speed production, meeting the increasing demand for quicker turn-arounds. The new machines provide quality and efficiency, particularly in very fine fibres such as cashmere and very fine Merino wool’, Giacomo Meucci says. ‘We also made a recent installation to Pendleton Woollen Mills in Portland, USA, a manufacturer of traditional woollen blankets and clothing.' AUTEFA Solutions OCTIR- Dragon Multitrave worsted and semiworsted cards guarantee high productivity without compromising the quality of the top. The result is fibre fineness from 14.5 - 40 microns and fiber length from 40 - 150mm. Read the full article

Carding Technology for finer microns, published in wool2yarnglobal 2021

As the natural fibre industry is increasingly shifting to finer microns, making tops from finer microns needs special care and specific machinery. Giacomo Meucci, sales director AUTEFA Solutions says, ‘we see this increased demand continuing, for Cashmere and other natural fibres. Our range of cards can process from the finest to the coarsest fibre and deliver excellent quality outcomes in wool, alpaca, and cashmere. Our cards run at a precise speed, guaranteeing consistency and evenness in top and yarn production. Tops will be some 2-3mm longer, creating the best yarn and a premium price. We believe that finer micron fibres run better on our AUTEFA cards, and that is why fibre users, particularly Cashmere manufacturers, prefer to use AUTEFA Solutions carding sets. Read the full article

AUTEFA presents innovative solutions for the textile industry

Higher productivity, sustainability and Industry 4.0 compatible solutions will be the highlights of AUTEFA presentations at the forthcoming ITMA Asia+ CITME in Shanghai. Latest machines from the business units Nonwovens Technology, Woollen Carding Technology and Baling Technology will be featured at the event later this month, at Hall 7, Stand A24.

The key advantages of the full range of the AUTEFA Solutions textile equipment portfolio will be explained, with a detailed focus on a number of specific innovations. Visitors will hear about the economic and technical benefits of AUTEFA as a systems supplier for full nonwovens lines in technology for carded-crosslapped needlepunching, aerodynamic web forming, spunlace production, and thermobonding. More information

‘Our machines deliver excellent quality outcomes in wool, alpaca, and cashmere. They can run at a precise speed, guaranteeing consistency and evenness in top and yarn production. Tops will be some 2-3mm longer the best yarn quality achievable’, says Giacomo Meucci.

‘In China and in Europe our machinery installations for cashmere woollen spinning are the preferred option. Ningbo Consinee in Zhejiang province will operate the most automated and modern plant for processing cashmere, and Gobi, the biggest spinning mill in Mongolia, uses our AUTEFA cards in its production’, he says. The OCTIR-Dragon Multitrave Worsted and Semi-worsted Cards guarantee high productivity without compromising the quality of the top. The result is fibre fineness from 14.5 - 40 microns and fiber length from 40 - 220mm. AUTEFA woollen carding sets feature feeding cylinders that reduce to 108mm, enabling better fibre control, producing a yarn with greater evenness and better CV and Uster values. These cards provide a more simplified opening of the card cover and increased throughput and blending action. More information

OCTIR Carding Set technology for all fibres

Spinners and weavers of a variety of different fibres including wool, noble fibres, and Synthetics know that streamlining their textile machinery needs with one provider is a better way to operate. AUTEFA Solutions manufactures OCTIR Cards for woollen, worsted, and semi worsted yarn, AUTEFA wool presses and a number of other textile machinery components. More information