Filling systems and lines for HDPE bottles

HDPE (high-density polyethylene) bottles offer distinct advantages in the packaging industry. Its light weight makes transportation more efficient and handling easier for manufacturers and consumers. In addition, HDPE is remarkably strong. HDPE's chemical resistance makes it the ideal choice for storing a wide variety of substances without damaging the material. HDPE is recyclable, which contributes to environmentally friendly disposal and reuse, reducing the environmental footprint.

The natural moisture barrier protects the contents of the bottle from external influences, which is particularly important when storing food or other sensitive substances. Finally, HDPE is versatile, making it suitable for a wide range of applications, from food packaging to household and industrial containers. All in all, HDPE bottles are a cost-effective, sustainable and environmentally friendly packaging solution that meets the needs of a wide range of industries.

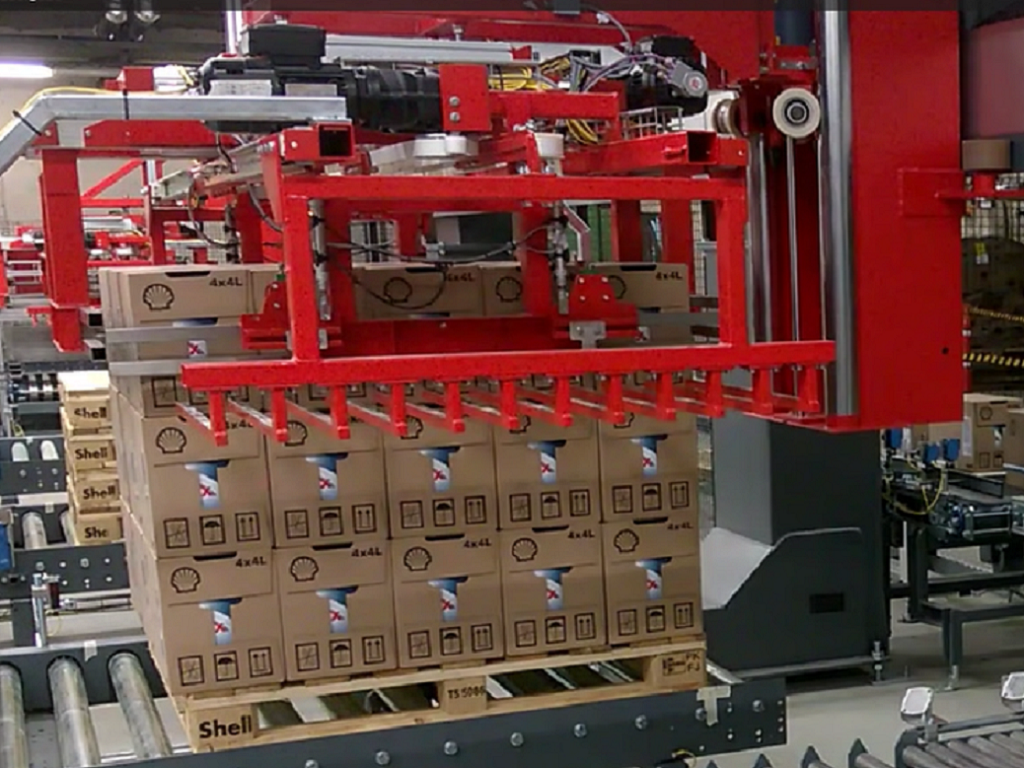

AUTEFA Solutions supplies complete lines for filling plants such as dairies, juice fillers, but also filling companies of household and cleaning products - from material receiving to fully automatic storage systems with integrated dispatch preparation. Depending on the requirements, multi-axis high-performance machines are used for depalletizing, packaging, palletizing or stacking. Fully automatically adjustable gripper heads and feeders streamline the process by significantly reducing set-up times, among other things. In the case of customer-specific requirements or special space conditions, the machine is adapted in order to develop an optimmal solution for the respective application.

HDPE (High-Density Polyethylene) bottles are widely used across various industries due to their excellent properties such as chemical resistance, strength, and durability. Here are some application areas of HDPE bottles in the industry:

- Food and Beverage Industry

- Packaging of Liquids: HDPE bottles are frequently used for packaging milk, juice, water, and other beverages. Their opacity helps protect the contents from light damage.

- Syrups and Sauces: These bottles are ideal for filling syrups, sauces, and dressings due to their chemical stability and resistance to high temperatures.

- Chemical Industry

- Storage and Transport of Chemicals: HDPE bottles are resistant to a variety of chemicals, including acids, bases, and solvents. They are commonly used for storing and transporting cleaning agents, laboratory chemicals, and other aggressive substances.

- Agricultural Chemicals: They are widely used for packaging pesticides, fertilizers, and other agricultural chemicals.

- Pharmaceutical Industry

- Packaging of Medications: HDPE bottles are used for filling liquid medications, syrups, and dietary supplements. Their safety for food and chemicals makes them a reliable choice for medical applications.

- Disinfectants: They are also used for packaging disinfectants and antiseptics.

- Cosmetics and Personal Care Industry

- Shampoos and Conditioners: HDPE bottles are frequently used for shampoos, conditioners, and other hair care products.

- Lotions and Creams: They are also commonly used for packaging lotions, creams, and other skincare products.

- Household Products Industry

- Cleaning Agents: HDPE bottles are ideal for packaging cleaning agents, fabric softeners, and bleaches due to their chemical resistance.

- Garden Products: They are also used for filling garden care products such as fertilizers and insecticides.

- Oil and Lubricant Industry

- Motor Oil and Lubricants: HDPE bottles are used for packaging motor oils, lubricants, and other automotive fluids due to their resistance to oils and greases.

- Construction Industry

- Construction Chemicals: HDPE bottles are used for packaging construction chemicals such as sealants, adhesives, and additives.

- Electronics Industry

- Electronics Cleaning Agents: They are used for special cleaning agents employed in the electronics industry.