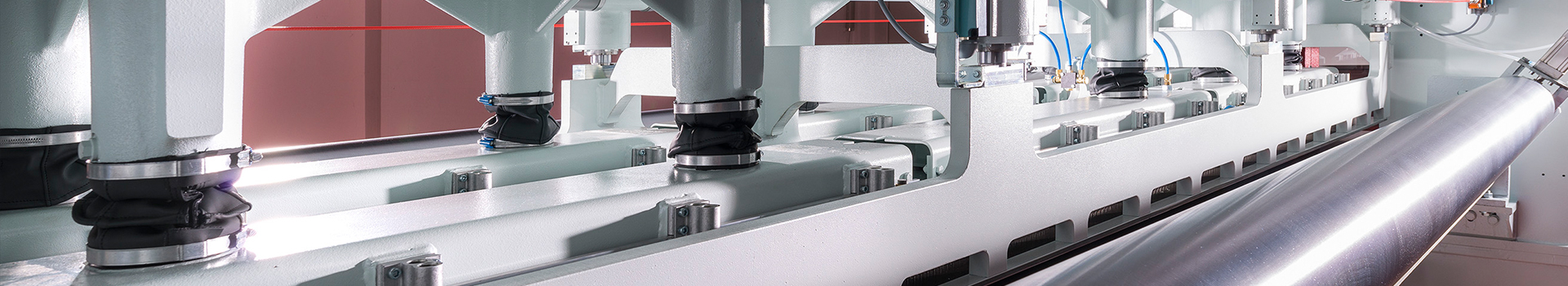

Success in the velour segment with Needle Looms from AUTEFA Solutions

AUTEFA Solutions' needle punching technology offers a path to success in the velour segment. With our advanced needle punching lines you can achieve exceptional results in the production of various velour fabrics such as automotive carpets, automotive trim, headliners, trunk liners and much more.

Our machines and lines are designed to meet the specific needs of this industry, allowing you to capitalize on opportunities for growth and success. Count on AUTEFA Solutions to provide you with the cutting-edge technology and expertise you need to excel in the velour needle punching market and achieve superior results.

Velour is commonly referred to as plush pile or velvet pile. It's a dense and short pile fabric with a soft velvety appearance. The upright finish of a velour fabric makes it perfect for a variety of applications.

- Max. continuous strokes per minute: 2200 rpm

- Working width: 1.2 m - 6.7 m

- Vertical stroke: 35 mm - 40 mm

- Needle pattern: 10000 - 17000 Needles/m

- Automotive carpets

- Automotive trims

- Headliners and trunk liners

- Home texiles

- Artificial turf

- Footwear and outerwear linings

- Soft toys