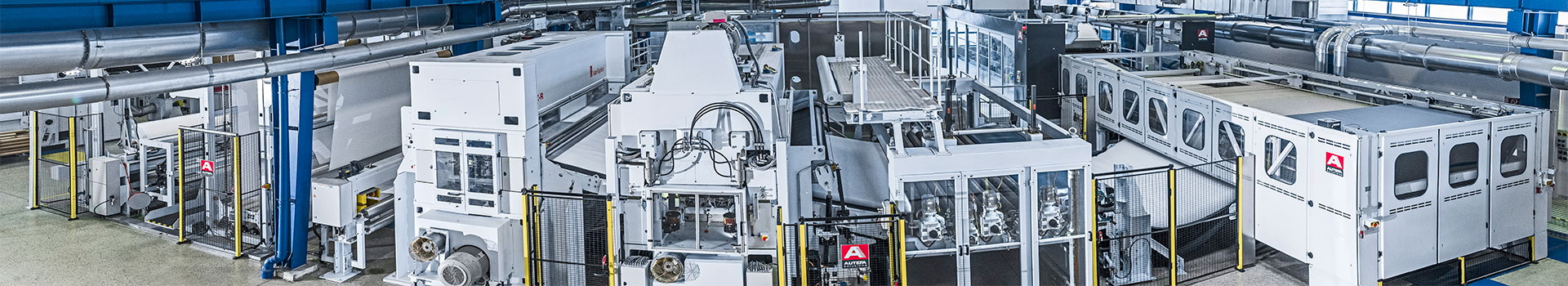

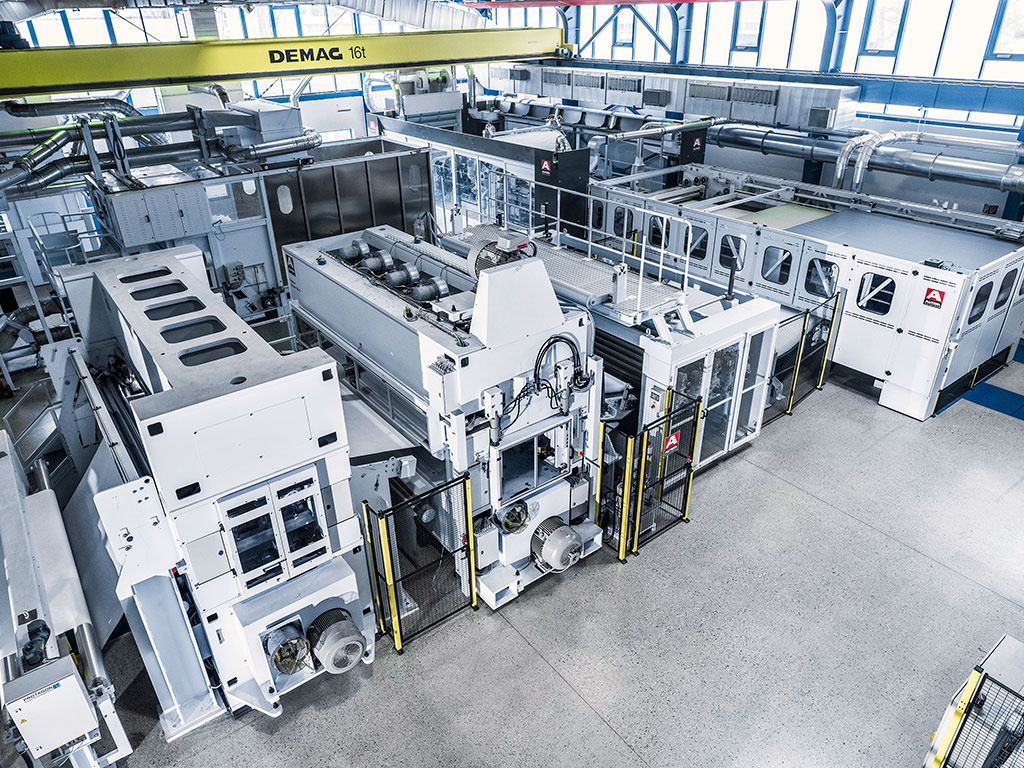

Neelde punching Lines

AUTEFA Solutions is a leading solution provider for turnkey needle punching lines. The major trends in the nonwovens industry of high productivity combined with low maintenance costs and high flexibility for different nonwoven products increase the demand for high quality machines from AUTEFA Solutions. All process steps are based on well known and worldwide proven technologies. In addition to the complete equipment,

AUTEFA Solutions offers comprehensive engineering services including start-up and production support as well as guarantees for quality and capacity. The main feature of the production lines is their outstanding flexibility, enabling nonwovens producers to produce a wide variety of products and truly unique fabrics.

- Crosslapper: layering speed up to 200 m/min, delivery speed up to 60 m/min

- Needle Punching: highest stroke frequencies in continuous operation, up to 3050 rpm

- Working widths up to 16 m

- Needle densities up to 30000 needles per meter

- Artificial leather

- Automotive felts

- Carpets and carpet backings

- Insulation materials for thermal and noise insulation

- Geotextiles

- Industrial wipes

- Technical Felts

- Blankets (needled)

- Clothing and furniture